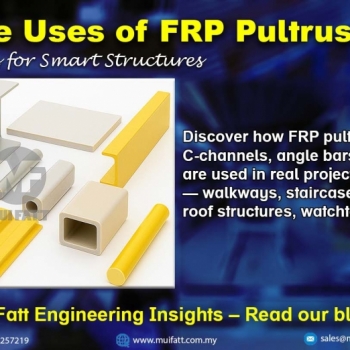

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Concrete Manhole Covers: Sizes, Types & Manufacturers - The Ultimate Guide

07 Jul 2023

Have you ever wondered what lies beneath the surface of our streets and sidewalks? Well, manhole covers hold the secret to accessing the underground utility systems that keep our cities running smoothly. These essential structures can be found all around us, from bustling roads to quiet corners of public areas. With their diverse shapes and sizes, manhole covers serve specific purposes depending on the infrastructure they protect. But why are these seemingly mundane objects so important? The answer is simple: safety and functionality. Manhole covers play a crucial role in ensuring that our infrastructure remains secure and operational. So next time you walk over one of these unassuming lids, remember the vital role they play in keeping everything connected below ground.

Introduction to the Importance of Manhole Covers

Manhole covers play a vital role in ensuring public safety and maintaining the integrity of underground utility systems. These sturdy covers serve as protective barriers, preventing people from accidentally falling into open utility holes. In addition to safeguarding individuals, manhole covers also act as a deterrent against unauthorized access to underground systems.

Protecting People from Accidents

One of the primary functions of manhole covers is to protect pedestrians and motorists from potential accidents. Without these covers, open utility holes pose a significant risk, especially during periods of low visibility or when people are distracted. By securely sealing off these openings, manhole covers provide peace of mind by reducing the chances of accidental falls and injuries.

Safeguarding Underground Systems

Beyond their role in preventing accidents, manhole covers contribute significantly to safeguarding underground infrastructure. They act as a barrier against debris, such as leaves, branches, or trash that could potentially clog pipes or obstruct drainage systems. Moreover, these covers help keep contaminants out of utility systems, ensuring clean water supply and efficient sewage management.

Maintaining Infrastructure Integrity

The absence of manhole covers would create numerous challenges for infrastructure maintenance. With open utility holes exposed to external elements like rainwater or snowfall, underground systems would be prone to damage and degradation over time. The cost associated with repairing and replacing damaged components would skyrocket without the protection offered by durable manhole covers.

To illustrate further the importance of manhole covers in maintaining infrastructure integrity:

-

Manholes located near roads might become susceptible to heavy traffic loads if left uncovered. This could lead to structural damage over time.

-

During construction activities nearby, debris can easily find its way into unprotected utility holes. This can result in blockages that disrupt regular operations.

-

Without proper coverage during extreme weather conditions like heavy rainfall or snowstorms, excess water can seep into underground systems causing flooding and subsequent damage.

Different Material of Manhole Covers

Manhole covers serve a crucial purpose in urban infrastructure, providing access to underground utility systems. These covers can be made from various materials, including concrete, cast iron, steel, and composite materials. Each material has its own unique advantages and suitability for specific applications.

-

Concrete: Manhole covers made from concrete are durable and resistant to heavy loads. They are commonly used in areas with low traffic volume.

-

Cast Iron: Cast iron manhole covers are known for their strength and durability. They are commonly used in high-traffic areas due to their ability to withstand heavy loads.

-

Steel: Steel manhole covers are lightweight and easy to handle. They are often used in areas where frequent access is required.

-

Composite materials: Manhole covers made from composite materials are lightweight, yet strong. They are resistant to corrosion and can be customized for specific applications.

Ultimately, the choice of material for manhole covers depends on various factors such as load-bearing capacity, durability, cost-effectiveness, and specific application requirements. Concrete manhole covers remain a popular choice due to their robustness, longevity, and ease of production. However, it's essential to assess individual project needs and consider alternative materials when necessary.

Benefits of Using Concrete Manhole Covers in Infrastructure

High Load-Bearing Capacity

Concrete manhole covers are renowned for their exceptional load-bearing capacity, making them the ideal choice for heavy traffic areas. Unlike other materials that may crack or deform under pressure, concrete manhole covers can withstand significant weight without compromising their structural integrity. This durability ensures that they can endure the constant passage of vehicles and pedestrians, providing long-lasting protection for underground infrastructure.

Corrosion Resistance

One of the key advantages of concrete manhole covers is their resistance to corrosion caused by chemicals or moisture commonly found in underground environments. These covers act as a reliable barrier against the harsh elements that would otherwise deteriorate metal or plastic alternatives over time. By utilizing concrete manhole covers, infrastructure owners can minimize maintenance costs and extend the lifespan of their underground structures.

Excellent Fire Resistance

Concrete manhole covers outperform other materials such as plastic or composite. The inherent properties of concrete make these covers highly resistant to fire, ensuring that they remain intact even in extreme heat conditions. This crucial feature not only protects the infrastructure below but also enhances overall safety in case of emergencies.

Aesthetic Customization

Concrete manhole covers offer a unique advantage in terms of aesthetic customization. With various designs and patterns available, these covers can be tailored to blend seamlessly with their surroundings or showcase artistic elements. Municipalities and urban planners often take advantage of this versatility to enhance the visual appeal of public spaces while maintaining functionality.

In addition to these benefits, concrete manhole covers provide several practical advantages for infrastructure projects:

-

Easy Installation: Concrete manhole covers are relatively simple to install, reducing labor costs and project timelines.

-

Low Maintenance: Once installed, these durable covers require minimal maintenance compared to alternative materials.

-

Longevity: Concrete's robust nature ensures that these covers have a longer lifespan than many other options.

-

Cost-Effective: Concrete manhole covers offer a cost-effective solution for infrastructure projects, providing long-term value and durability.

Manufacturing Process for Concrete Manhole Covers

Concrete manhole covers are essential components of urban infrastructure, providing access to underground utility networks. The manufacturing process for these covers involves several steps to ensure their durability and functionality.

Preparing the Mold

The first step in the manufacturing process is preparing a mold based on the desired specifications of the concrete manhole cover. The mold serves as a template that determines the shape and size of the final product. It is typically made from materials such as steel or fiberglass, known for their strength and ability to withstand repeated use.

Mixing and Pouring

Once the mold is ready, a mixture of cement, aggregates, water, and additives is prepared. Cement acts as a binding agent, while aggregates like sand or crushed stone provide strength and stability to the cover. Water is added to achieve proper consistency, allowing for easy pouring into the mold. Additives may be included to enhance specific properties of the concrete mix, such as increasing its resistance to corrosion or improving its load-bearing capacity.

The carefully measured ingredients are mixed thoroughly until they form a homogeneous blend. This ensures that all elements are evenly distributed within the mixture, contributing to consistent quality across each manhole cover produced.

After achieving an optimal mix, it is poured into the prepared mold. Care must be taken during this stage to prevent air bubbles from forming within the concrete. Vibrators may be used to eliminate any trapped air pockets and ensure maximum density throughout.

Curing Process

Once poured into the mold, the concrete mixture undergoes a curing process where it gradually hardens over time. Curing allows chemical reactions within the cementitious materials to take place, resulting in increased strength and durability.

The duration of curing depends on various factors such as environmental conditions and specific mix design. Typically, it takes several days for concrete manhole covers to reach sufficient strength before they can be removed from their molds without compromising their integrity.

Quality Checks

Before concrete manhole covers are deemed ready for installation, they undergo rigorous quality checks. These checks ensure that the covers meet industry standards and can withstand the demands of their intended use.

Quality control measures may involve visual inspections, dimensional measurements, and load testing. Visual inspections check for any surface defects or imperfections that could compromise the cover's integrity. Dimensional measurements verify that the cover conforms to specified size requirements.

Load testing involves subjecting the manhole cover to simulated loads to assess its structural strength. This test ensures that it can bear the weight of vehicles or pedestrians without cracking or breaking under pressure.

Once a concrete manhole cover successfully passes all quality checks, it is considered ready for installation in urban areas where it will serve as a reliable access point to underground utility networks.

Essential Tool for Concrete Manhole Covers Manufacture: Mold

The mold plays a vital role in the manufacturing process of concrete manhole covers. It is responsible for determining the shape, size, and design of the final product. Without a high-quality mold, it would be impossible to produce durable and reliable manhole covers.

Molds can be made from various materials, including fiberglass reinforced plastic (FRP) or steel. Each material option has its own advantages and considerations. Here are some of the common materials used for concrete manhole cover molds:

-

Fiberglass Reinforced Plastic (FRP): FRP molds are lightweight, durable, and resistant to corrosion. They offer excellent dimensional stability and can withstand high temperatures without warping or distorting.

-

Steel: Steel molds are known for their strength and durability. They can withstand heavy use and provide precise shaping capabilities. However, steel molds may require more maintenance to prevent rusting.

-

Rubber: Rubber molds are flexible and allow for intricate designs on the manhole covers. They are easy to work with and provide good release properties when demolding the finished product.

-

Aluminum: Aluminum is both strong and lightweight. This metal is commonly used for this purpose and is highly suitable due to its properties.

-

Plastic: Plastic is another material that people often use to make manhole covers mold. They are a great option due to their light weight, durability, and ability to resist corrosion.

Choosing the right material for concrete manhole cover molds depends on several factors such as budget, production volume, desired design complexity, and expected lifespan of the mold. Manufacturers need to consider these factors carefully to ensure optimal performance and cost-effectiveness.

The quality and precision of the mold directly impact the quality of the finished manhole cover. A well-designed mold ensures that every detail is accurately reproduced in each cast piece, resulting in uniformity across all products. This is crucial for maintaining consistency in shape, size, texture, and overall appearance.

Moreover, a high-quality mold minimizes defects such as air pockets or uneven surfaces that could compromise structural integrity or aesthetics. By investing in a reliable mold manufacturing process, manufacturers can significantly reduce waste due to rejected or flawed products.

Why Fiberglass Reinforced Plastic is a Suitable Material for Concrete Manhole Cover Mold?

Fiberglass reinforced plastic (FRP) is an excellent choice for creating molds for concrete manhole covers due to its unique properties and durability. Let's explore why FRP is the perfect material for this purpose.

High Strength-to-Weight Ratio

One of the key advantages of using FRP for manhole cover molds is its exceptional strength-to-weight ratio. FRP combines the strength of fiberglass with the lightweight nature of plastic, resulting in a material that can withstand heavy loads without being excessively bulky. FRP molds are super strong and can handle the heavy weight and pressure from pouring concrete on them over and over again.

Non-Reactive to Chemicals

Concrete mixtures often contain various chemicals that can react with certain materials, leading to degradation or corrosion over time. However, FRP is non-reactive to these chemicals commonly found in concrete mixtures, ensuring long-lasting performance. This resistance to chemical reactions helps maintain the integrity and structural stability of the mold, preventing any deterioration that could compromise its functionality.

Smooth Surface Facilitating Easy Demolding

The smooth surface of FRP molds plays a crucial role in facilitating the demolding process of concrete manhole covers. Unlike other materials that may stick or cause damage during demolding, FRP ensures a seamless release without any complications. The inherent low friction properties of FRP prevent adhesion between the mold and the concrete, allowing for easy removal while maintaining the desired shape and finish quality.

Withstanding Repeated Use

There is a big need for manhole covers in different industries, so they are made in large quantities. Therefore, it is essential that their molds can endure repeated use without significant wear or deformation. Fortunately, FRP exhibits remarkable durability even after multiple castings. Its robustness enables it to withstand continuous cycles of molding and demolding without losing shape or structural integrity.

Cost Analysis for Concrete Manhole Covers Mold

The cost of manufacturing a concrete manhole cover mold depends on several factors, including the choice of material, complexity of design, and production volume. It is important to consider these factors when analyzing the overall cost involved in producing concrete manhole covers.

|

Material Choice |

Price Level |

Durability |

Expected Lifespan |

Maintenance Requirements |

|---|---|---|---|---|

|

Steel |

Expensive |

Strong and durable |

Long lifespan |

Minimal maintenance, occasional cleaning and rust prevention measures |

|

Plastic |

More affordable |

Less durable |

Shorter lifespan |

Regular inspections and potential repairs |

|

Aluminum |

Balance between cost and durability |

Sufficient strength |

Moderate lifespan |

Moderate maintenance |

|

Rubber |

Lower upfront cost |

Flexible and easy to use |

Shorter lifespan |

Moderate maintenance |

|

Fiberglass-Reinforced Plastic (FRP) |

Higher initial investment |

Highly durable and reusable |

Long lifespan |

Relatively low maintenance, can withstand various environmental factors |

Material Choice

There are various options available, including steel, plastic, aluminum, rubber, and fiber-reinforced polymer (FRP). Each material has its own price level and characteristics that impact the overall cost.

-

Steel: Steel molds are known for their strength and durability. However, they can be expensive compared to other materials.

-

Plastic: Plastic molds offer a more affordable option but may not be as durable or long-lasting as steel or FRP molds.

-

Aluminum: Aluminum molds provide a balance between cost and durability. They are lighter than steel molds but still offer sufficient strength.

-

Rubber: Rubber molds are often used for smaller-scale production due to their flexibility and ease of use. They tend to have a lower upfront cost.

-

FRP: Fiber-reinforced polymer (FRP) molds may require a higher initial investment compared to other materials. However, they offer significant long-term cost savings due to their durability and reusability.

Price Level and Durability

Considering the price level of each material is crucial when conducting a cost analysis. While some materials may have lower upfront costs, they might not be as durable or long-lasting as others. It's essential to strike a balance between affordability and longevity.

For instance, although plastic molds are generally cheaper than steel or FRP molds initially, they may wear out faster over time due to their lower durability. On the other hand, investing in an FRP mold might involve higher upfront costs but will pay off in the long run due to its exceptional durability.

Expected Lifespan

Another factor to consider in the cost analysis of concrete manhole cover molds is their expected lifespan. Steel molds, known for their strength, can withstand heavy usage and have a longer lifespan compared to plastic or rubber molds.

However, FRP molds are particularly advantageous in terms of longevity. They can endure high levels of wear and tear without compromising their structural integrity. This makes them an excellent choice for long-term use, reducing the need for frequent mold replacements and ultimately lowering costs.

Maintenance Requirements

When evaluating the overall cost of manufacturing concrete manhole cover molds, it is essential to account for maintenance requirements. Some materials may require more frequent repairs or replacements due to wear and tear or exposure to harsh conditions.

more frequent repairs or replacements due to wear and tear or exposure to harsh conditions.

Steel molds typically require minimal maintenance but may need occasional cleaning and rust prevention measures. Plastic molds might be susceptible to cracking or warping over time, necessitating regular inspections and potential repairs.

FRP molds, however, are relatively low-maintenance due to their inherent durability. They can withstand various environmental factors without significant degradation, resulting in reduced maintenance costs over the mold's lifespan.

Factors to Consider When Choosing Concrete Manhole Covers Mold

Mold material compatibility with concrete mixture

It is very important to select the correct material for the mold. The mold must work well with the specific concrete mixture that is being used for the project. Different mixtures may need different mold materials to guarantee a good result.

For instance, FRP molds are strong and can handle the pressure and weight of concrete. They make the concrete smooth and can be used many times, saving money. Rubber molds are flexible and easy to remove. They work well for complex designs and don't damage the finished product.

Dimensional accuracy required for specific project needs

The dimensional accuracy of a manhole cover is essential to ensure a proper fit within the infrastructure system. When choosing a mold, it's crucial to consider the specific project requirements regarding size, shape, and thickness.

FRP molds are often the top choice for projects that require precise measurements, like those that involve standardized infrastructure systems or strict regulations. These molds are highly favored because they consistently deliver accurate results, thanks to their strong and stable nature.

However, if customization or unique designs are required, rubber molds offer greater flexibility in achieving dimensional accuracy. Rubber molds can easily replicate intricate patterns or textures while maintaining precision in size and shape.

Cost-effectiveness and long-term durability of the mold

Cost-effectiveness is an important factor when choosing a concrete manhole cover mold, especially for large-scale projects where multiple covers need to be produced. It's crucial to evaluate both upfront costs and long-term durability.

FRP molds might cost more at first than rubber molds, but they are really tough and last a long time. If you take good care of them, FRP molds can be used over and over again without getting worn out or changing shape. This makes them a smart choice in the end because they save you money.

On the other hand, rubber molds are generally more affordable upfront but may require replacement after a certain number of uses. The lifespan of rubber molds depends on factors such as the complexity of the design and the frequency of use. For projects with limited production needs or frequent design changes, rubber molds can be a cost-effective option.

Ability to produce consistent and high-quality manhole covers

Consistency and quality are paramount when manufacturing concrete manhole covers. The chosen mold should be capable of producing uniform and reliable results throughout the production process.

FRP molds excel in providing consistent results due to their rigid structure. They ensure that each manhole cover cast using the mold maintains uniformity in size, shape, and surface finish. This is particularly important for projects requiring standardized covers across an infrastructure network.

Rubber molds also have the ability to produce high-quality manhole covers, especially. Their flexibility allows for detailed replication while maintaining overall quality standards.

Maintenance and Cleaning Tips for Concrete Manhole Covers Mold

Regularly clean the mold after each use to remove any residual concrete or debris. This simple step is crucial in ensuring the longevity and quality of your concrete manhole covers. Leaving concrete residue or debris on the mold can lead to imperfections in the final product, compromising its structural integrity and aesthetic appeal.

Inspect the mold for any signs of wear, damage, or buildup that may affect the quality of future manhole covers. Over time, molds can develop cracks, chips, or other forms of damage that could result in imperfect casts. By closely examining the mold before each use, you can identify any issues and address them promptly. Be on the lookout for excessive buildup or residue inside the mold as it can impede proper casting.

Properly store the mold in a dry and protected environment when not in use to prevent degradation. Moisture and exposure to harsh elements can gradually deteriorate your concrete molds over time. To avoid this, find a suitable storage space that is dry and shielded from extreme temperatures. Consider using protective coverings such as plastic sheets or cases to further safeguard your molds from potential damage.

Follow manufacturer's guidelines for maintenance and cleaning specific to the chosen material. Different types of molds may require specific care instructions based on their composition. Manufacturers often provide guidelines regarding cleaning agents, recommended cleaning frequency, and other maintenance tips tailored to their particular products. Adhering to these instructions ensures optimal performance and extends the lifespan of your molds.

There are several effective methods you can employ:

-

Use a high-pressure washer: A powerful jet of water helps dislodge stubborn residue from both smooth surfaces and intricate details within the mold.

-

Scrub with a brush: For more persistent stains or debris, gently scrubbing with a soft-bristle brush can help loosen them.

-

Apply cleaning solutions: Depending on the manufacturer's recommendations, you may use mild detergents or specially formulated mold cleaners to remove tough stains. Always rinse thoroughly after using cleaning agents.

-

Inspect for hidden areas: Pay attention to hard-to-reach corners and crevices where debris might accumulate unnoticed. Utilize specialized tools like small brushes or compressed air to ensure thorough cleaning.

By following these maintenance and cleaning tips, you can keep your concrete manhole cover molds in excellent condition, ensuring consistent quality in every cast. Remember, regular upkeep not only enhances the performance of your molds but also contributes to the overall durability and reliability of the final product.

The Future of Concrete Manhole Covers

Sustainable Materials for Manufacturing

Ongoing research in the field of concrete manhole covers aims to develop more sustainable materials for their manufacturing. With a growing focus on environmental responsibility, manufacturers are exploring alternatives to traditional concrete that can reduce carbon emissions and minimize resource consumption. By utilizing recycled materials or incorporating additives like fly ash or slag, researchers hope to create manhole covers with a lower environmental impact.

Innovative Coatings and Smart Sensors

Innovations such as self-cleaning coatings or smart sensors integrated into concrete manhole covers are being explored to enhance their functionality. Self-cleaning coatings could help prevent the accumulation of debris and pollutants on the cover's surface, reducing maintenance requirements and ensuring better visibility. Smart sensors could be used to monitor factors like water levels or gas concentrations within the sewer system, providing valuable data for maintenance teams and improving overall infrastructure management.

Lightweight yet Durable Solutions

The demand for lightweight yet durable manhole cover solutions is expected to increase in the future. Traditional concrete covers can be heavy and challenging to handle during installation or maintenance activities. Manufacturers are now focusing on developing lighter alternatives without compromising strength and durability. Fiber-reinforced composites or high-performance polymers may offer viable solutions by combining strength with reduced weight, making handling easier while maintaining structural integrity.

Advancements in Manufacturing Techniques

Advancements in manufacturing techniques have the potential to revolutionize concrete manhole cover production processes. Traditional methods often involve manual labor-intensive procedures that can be time-consuming and costly. However, emerging technologies such as 3D printing or automated molding systems hold promise for more cost-effective production processes. These advancements could streamline manufacturing, reduce waste, and improve overall efficiency in delivering quality manhole covers.

As concrete manhole covers continue to evolve, sustainability remains a key focus area alongside enhanced functionality and improved manufacturing processes. By embracing innovative approaches like using sustainable materials, integrating smart sensors, and exploring lightweight alternatives, the industry aims to meet the growing demand for efficient and environmentally responsible solutions.

Conclusion: Understanding the Importance of Concrete Manhole Covers and The Right Mold

Concrete manhole covers play a crucial role in infrastructure, providing access to underground utility systems while ensuring safety for pedestrians and vehicles. By using concrete manhole covers, you can enjoy numerous benefits such as durability, strength, and resistance to wear and tear.

The right mold is of utmost importance. A suitable mold material for concrete manhole covers is fiberglass reinforced plastic (FRP). FRP molds offer several advantages including flexibility, ease of use, and cost-effectiveness.

Considering the cost analysis for concrete manhole cover molds, FRP molds prove to be a wise investment. Their affordability combined with their long lifespan makes them an economical choice for manufacturers.

While choosing a concrete manhole cover mold, there are certain factors that should be taken into account. These include the size and shape requirements of the cover, the production capacity needed, and the quality standards that must be met.

To ensure longevity and optimal performance of your concrete manhole cover mold, regular maintenance and cleaning are essential. Simple tips like keeping the mold clean from debris or applying release agents can significantly extend its lifespan.

Looking towards the future, concrete manhole covers will continue to play a vital role in infrastructure development. As technology advances, we can expect innovations in design and materials that further enhance their performance and durability.

In conclusion, understanding the importance of concrete manhole covers goes hand in hand with recognizing the significance of choosing the right mold material. By opting for high-quality fiberglass reinforced plastic molds, you can ensure efficient production processes while maintaining cost-effectiveness. So invest wisely in your manufacturing equipment today! Talk to us, WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

FAQs

Q: Are concrete manhole covers suitable for heavy traffic areas?

Concrete manhole covers are designed to withstand heavy traffic loads without compromising their structural integrity. They provide reliable protection even in busy urban environments.

Q: Can concrete manhole covers be customized to fit specific project requirements?

Yes, concrete manhole covers can be customized to meet specific size and shape requirements. This flexibility allows them to be seamlessly integrated into various infrastructure projects.

Q: Are there any environmental benefits of using concrete manhole covers?

Concrete manhole covers have a lower carbon footprint compared to other materials, making them an environmentally friendly choice. Their durability reduces the need for frequent replacements, further reducing waste.

Q: How long do concrete manhole covers typically last?

When properly maintained, concrete manhole covers can last for several decades. Their inherent strength and resistance to wear ensure longevity in demanding conditions.

Q: Are there regulations or standards that govern the manufacturing of concrete manhole covers?

Yes, various national and international standards exist to ensure the quality and performance of concrete manhole covers. These standards help maintain consistency and safety across different regions.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

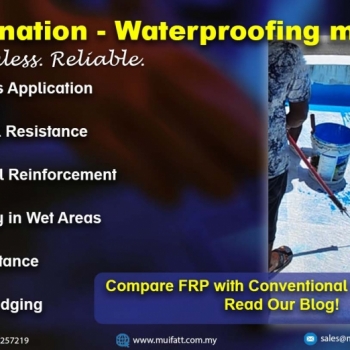

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

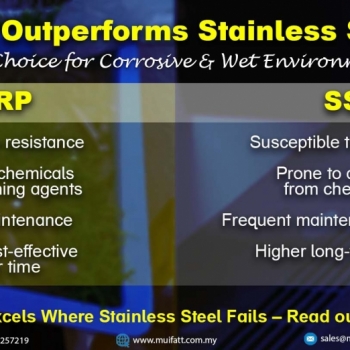

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

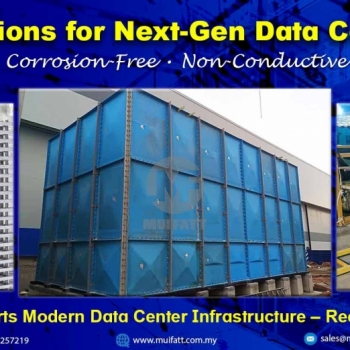

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.