FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions

20 Jun 2024

Odor Control in Wastewater Treatment Plants with FRP Solution: A Complete Guide

Odor Control in Wastewater Treatment Plants with FRP Solution: A Complete Guide

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions- The Odor Conundrum

- Current Odor Control Methods

- The Fiberglass Advantage

- Case Study: Successful Implementation of Fiberglass Solutions in a Malaysian Wastewater Treatment Plant

- Conclusion

- Frequently Asked Questions

- What are the main causes of odor in wastewater treatment plants?

- How fo fiberglass solutions compare to traditional odor control methods?

- What make fiberglass resistant to corrosion and chemicals?

- Can fiberglass odor control solutions be customized for specific plant needs?

- What are the long-term benefits of using fiberglass for odor control?

Banishing Odor Woes in Wastewater Treatment Plants: Leveraging Fiberglass for Lasting Solutions and Air Scrubbing in Vapor Phase for Public Health

The battle against odors in wastewater treatment plants is an ongoing challenge faced by authorities and operators worldwide, including those in Malaysia. The offensive odors not only disrupt the surrounding community but also indicate potential operational inefficiencies and environmental concerns. In this article, we delve into the persistent odor problem in Malaysian wastewater treatment plants and explore how fiberglass solutions offer a sustainable and cost-effective remedy for odors.

The Odor Conundrum

Odor emissions from wastewater treatment plants in Malaysia are a result of biological and chemical processes occurring during the treatment of sewage and industrial effluents. Compounds such as hydrogen sulfide (H2S), ammonia (NH3), and volatile organic compounds (VOCs) contribute to the foul smells, creating nuisance for nearby residents and businesses. Besides being a nuisance, these odors can also pose health risks and tarnish the reputation of treatment facilities.

Understanding the Sources of Odor

The primary sources of odor in wastewater treatment plants stem from the breakdown of organic matter and the presence of industrial pollutants. During the treatment process for wastewater odor control, microorganisms decompose organic materials, releasing gases like hydrogen sulfide and ammonia. Additionally, industrial effluents often contain volatile organic compounds that contribute to the overall odor profile.

Impact on Communities and Health Risks

The impact of odor emissions extends beyond mere discomfort. Prolonged exposure to certain odorous compounds can pose health risks, such as respiratory issues, headaches, and nausea. Furthermore, the presence of persistent odors can lead to community complaints, legal actions, and a negative perception of the treatment facility.

Current Odor Control Methods

Traditionally, wastewater treatment plants employ various odor control methods to mitigate foul smells, including:

Chemical Dosing

Chemical dosing involves the use of chemicals to neutralize odorous compounds. While effective, this method can be costly and requires continuous monitoring and adjustment.

Biofiltration

Biofiltration uses microorganisms to degrade odorous compounds. This method is environmentally friendly but can be limited by factors such as temperature and moisture levels.

Activated Carbon Adsorption

Activated carbon adsorption captures odorous compounds on the surface of activated carbon. It is effective but requires regular replacement of the carbon media, leading to ongoing maintenance costs.

Air Scrubbing

Air scrubbing involves passing odorous air through a scrubbing solution to remove contaminants. While efficient, it can be complex to operate and maintain.

The Fiberglass Advantage

Fiberglass emerges as a game-changer in the fight against odor in wastewater treatment plants, offering a sustainable and cost-effective solution. Fiberglass-reinforced products, such as covers, enclosures, and ductwork, provide an impermeable barrier against odor emissions, preventing them from escaping into the surrounding environment. Unlike conventional materials like steel or concrete, fiberglass is resistant to corrosion, chemical degradation, and UV exposure, ensuring long-lasting odor control with minimal maintenance requirements.

Fiberglass emerges as a game-changer in the fight against odor in wastewater treatment plants, offering a sustainable and cost-effective solution. Fiberglass-reinforced products, such as covers, enclosures, and ductwork, provide an impermeable barrier against odor emissions, preventing them from escaping into the surrounding environment. Unlike conventional materials like steel or concrete, fiberglass is resistant to corrosion, chemical degradation, and UV exposure, ensuring long-lasting odor control with minimal maintenance requirements.

Benefits of Fiberglass Odor Control Solutions

Corrosion Resistance

Fiberglass products are impervious to corrosion, making them ideal for use in the harsh, corrosive environments of wastewater treatment plants. This corrosion resistance extends the lifespan of odor control structures and minimizes the need for frequent replacements or repairs.

Chemical Compatibility

Fiberglass exhibits excellent chemical resistance, allowing it to withstand exposure to a wide range of odorous compounds without degradation or deterioration. This chemical inertness ensures reliable odor control performance over time.

Low Maintenance

Fiberglass odor control solutions require minimal maintenance compared to traditional materials, reducing operational costs and downtime associated with upkeep and repairs. This low maintenance requirement translates to long-term savings for wastewater treatment facilities.

Case Study: Successful Implementation of Fiberglass Solutions in a Malaysian Wastewater Treatment Plant

Project Background and Objectives

In a major wastewater treatment plant located in Malaysia, persistent odor issues were causing community complaints and operational challenges. The plant management sought a sustainable and long-lasting solution to address these concerns while minimizing maintenance costs.

Implementation Process

The project involved the installation of fiberglass covers and enclosures over critical odor-emitting sources within the treatment plant. Custom-designed fiberglass ductwork was also implemented to channel odorous air to a central treatment system. The installation process was carried out with minimal disruption to ongoing operations.

Results and Benefits

Following the implementation of fiberglass solutions, the treatment plant experienced a significant reduction in odor emissions. Community complaints dropped substantially, and the plant's reputation improved. Additionally, the low maintenance requirements of the fiberglass products resulted in cost savings and enhanced operational efficiency.

Conclusion

Odor emissions pose significant challenges to wastewater treatment plants in Malaysia, affecting nearby communities and operational efficiency. By embracing fiberglass odor control solutions, these facilities can effectively mitigate odor issues while reducing maintenance costs and ensuring long-term sustainability. As Malaysia strives towards environmental stewardship and infrastructure resilience, fiberglass emerges as a versatile and reliable ally in the quest for odor-free wastewater treatment.

Talk to us about your project today! WhatsApp or email – sales@muifatt.com.my

Frequently Asked Questions

What are the main causes of odors in wastewater treatment plants?

The main causes of odor in wastewater treatment plants are the biological and chemical processes during the treatment of sewage and industrial effluents. Compounds like hydrogen sulfide (H2S), ammonia (NH3), and volatile organic compounds (VOCs) contribute significantly to the foul smells.

How fo fiberglass solutions compare to traditional odor control methods?

Fiberglass solutions provide a more sustainable and cost-effective approach compared to traditional methods like chemical dosing, biofiltration, activated carbon adsorption, and air scrubbing. They offer long-lasting odor control with minimal maintenance requirements due to their resistance to corrosion, chemical degradation, and UV exposure.

What make fiberglass resistant to corrosion and chemicals?

Fiberglass is composed of glass fibers embedded in a resin matrix, which provides excellent resistance to corrosive environments and chemical exposure. This makes it ideal for use in the harch conditions found in wastewater treatment plants.

Can fiberglass odor control solutions be customized for specific plant needs and choice?

Yes, fiberglass products can be customized to fit specific requirements of wastewater treatment plants. This includes custom sizes and shapes for covers, enclosures, and ductwork to ensure optimal odor control and integration with existing infrastructure.

What are the long-term benefits of using fiberglass for odor control in wastewater treatment solutions?

The long-term benefits of using fiberglass for odor control include extended lifespan of odor control structures, reduced maintenance costs, improved operational efficiency, and enhanced environmental sustainability. These benefits contribute to significant cost savings and more reliable performance over time.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

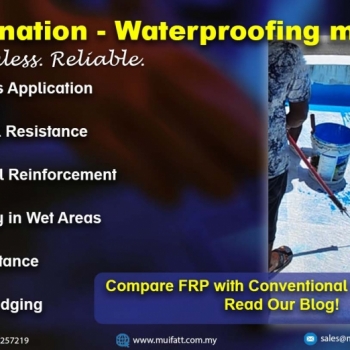

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

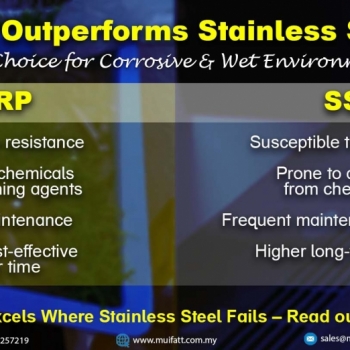

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

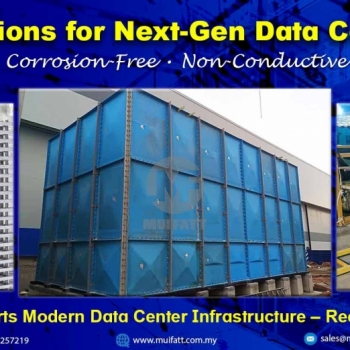

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.