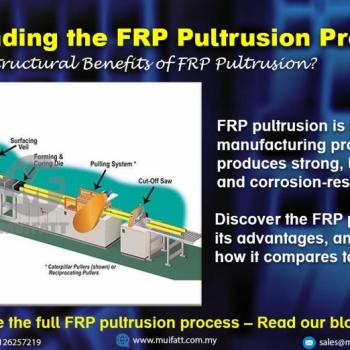

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

The Importance of Compliance with DOSH Regulations for Fiberglass Application

22 May 2023

In Malaysia, the Department of Occupational Safety and Health (DOSH) regulates and sets requirements for various occupational safety and health matters, including the application of fiberglass in both the commercial and industrial sectors.

This article provides valuable insights into the risks of fiberglass application, the importance of safety measures, regulatory compliance, and best practices for a secure working environment.

Understanding the Risks of Fiberglass Application: Protecting Workers and Ensuring Safety

Fiberglass, also known as fiberglass-reinforced plastic (FRP), is a versatile composite material widely used in various industries for its strength, durability, and insulation properties. However, it comes with inherent risks that must be carefully managed to protect workers and ensure a safe working environment.

Fiberglass, also known as fiberglass-reinforced plastic (FRP), is a versatile composite material widely used in various industries for its strength, durability, and insulation properties. However, it comes with inherent risks that must be carefully managed to protect workers and ensure a safe working environment.

Common risks that underlying beneath fiberglass application

Respiratory Hazards

Fiberglass materials can generate airborne dust particles, which, if inhaled, can pose health risks. Continuous exposure to fiberglass dust can lead to respiratory issues such as coughing, wheezing, and difficulty breathing. Prolonged or unprotected exposure to fiberglass dust may also cause more serious respiratory conditions. Implementing appropriate safety measures and providing respiratory protection is essential to safeguard workers health.

Skin Irritation and Contact Hazards

Direct contact with fiberglass can lead to skin irritation, redness, itching, and rashes. Certain individuals may also develop allergic reactions to fiberglass, resulting in more severe skin symptoms. Minimizing these risks requires providing workers with proper clothing and gloves.

Eye Injuries and Hazards

Fiberglass particles can be abrasive and may cause eye injuries if they come into contact with the eyes. This can lead to irritation, redness, and potentially more serious injuries if the particles penetrate the eye. Protecting workers eyes from fiberglass particles is paramount.

Toxicity and Chemical Exposure

Some fiberglass materials and associated chemicals used during the application process may have toxic properties. Workers can be exposed to these chemicals through inhalation, skin contact, or ingestion. Prolonged or repeated exposure to toxic chemicals may lead to various health issues, including respiratory problems, skin disorders, and other systemic effects. Proper ventilation is crucial to limit chemical exposure and airborne contamination.

Fire and Electrical Hazards

Improper handling, storage, or use of fiberglass materials near potential ignition sources can result in fire hazards. Additionally, electrical hazards may arise when working with electrical equipment or tools in proximity to fiberglass materials. Mitigating fire risks and electrical hazards is crucial in ensuring a safe working environment.

Ergonomic and Physical Hazards (Musculoskeletal Disorders)

Fiberglass application often involves repetitive tasks, manual lifting, and working in awkward positions. These factors can contribute to musculoskeletal disorders such as strains, sprains, and repetitive motion injuries. Promoting safe lifting and handling techniques, along with compliance with ergonomic practices, ensures the well-being of workers and minimizes the risk of injuries.

Understanding the risks involved in fiberglass application is paramount for safeguarding workers and maintaining a safe workplace environment. By addressing the above potential hazards, employers can protect their workforce and ensure compliance with safety regulations. Prioritizing worker safety not only mitigates potential risks but also fosters a culture of care and responsibility within the fiberglass application industry.

Adherence to DOSH Regulations and Requirements

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE)

DOSH mandates the use of appropriate personal protective equipment, including protective clothing, gloves, eye protection, and respiratory protection. Employers are responsible for providing suitable PPE and ensuring its proper usage.

Ventilation and Dust Control

DOSH requires employers to ensure that work areas are properly ventilated, which may involve using local exhaust ventilation systems or providing sufficient fresh air circulation. Regular cleaning helps prevent the buildup of fiberglass dust.

Proper Handling and Storage / Hazard Communication

One of the key aspects of DOSH requirements is the proper handling and storage of fiberglass materials. Employers must ensure that fiberglass products are stored in a dry and well-ventilated area, away from potential ignition sources. Additionally, implementing a hazard communication program to inform workers about the potential risks associated with fiberglass application is necessary. This includes labelling containers properly and providing safety data sheets (SDS) for relevant materials.

Training and Competency

DOSH requires employers to provide adequate training and supervision to workers involved in fiberglass application. This training should cover topics such as safe work practices, proper handling and storage of materials, hazard identification, emergency response procedures, and the use of personal protective equipment. Regular refresher courses should be conducted to reinforce safety knowledge and ensure compliance.

Equipment and Tools

Equipment and Tools

Employers are responsible for providing suitable equipment and tools for fiberglass application. This includes ensuring that the equipment is properly maintained, inspected regularly, and operated safely. Any damaged or malfunctioning equipment should be repaired or replaced promptly.

Worksite Safety

DOSH emphasizes the importance of maintaining a safe worksite during fiberglass application. This involves ensuring proper housekeeping practices to prevent slips, trips, and falls, as well as implementing measures to control potential sources of ignition and fire hazards.

Risk Assessment and Control

Risk Assessment and Control

Employers must conduct thorough risk assessments and implement appropriate control measures to minimize or eliminate identified risks. This involves identifying potential hazards associated with the materials, tools, and techniques used, as well as assessing the level of risk. Based on the assessment, appropriate control measures, such as engineering controls or administrative controls, should be implemented to minimize or eliminate identified risks.

Emergency Preparedness

DOSH requires employers to have emergency response plans in place for fiberglass-related incidents. This includes procedures for handling accidents, spills, or injuries that may occur during the application process. Adequate first aid equipment, emergency contact information, and evacuation plans should be readily available to respond effectively to emergencies.

Benefits of Compliance

Adhering to DOSH requirements for fiberglass application brings several benefits to both employers and workers. It reduces the risk of occupational hazards and potential injuries, ensures workers well-being and safety, and promotes employee morale and productivity. Compliance also helps prevent environmental contamination, enhances the company’s reputation, attracts potential clients, and foster long-term relationship.

Complying with Malaysia DOSH requirements for fiberglass application is essential to ensure the safety of workers and maintain a secure working environment. Employers must prioritize proper handling, storage, ventilation, and the use of personal protective equipment when working with fiberglass materials. Training programs, risk assessments, and emergency preparedness are crucial elements in meeting DOSH standards. By adhering to these requirements, employers can protect their workers, prevent accidents, and contribute to a safer and healthier workplace environment in the fiberglass application industry.

Talk to us for your queries today! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

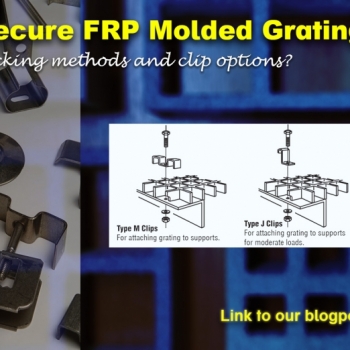

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

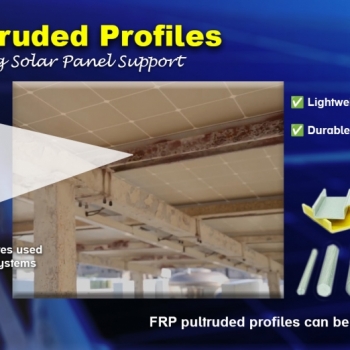

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

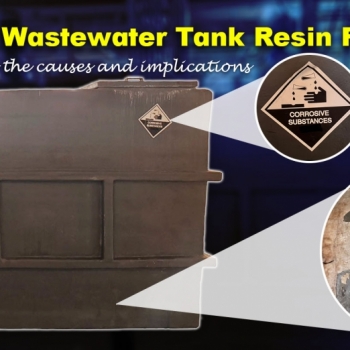

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

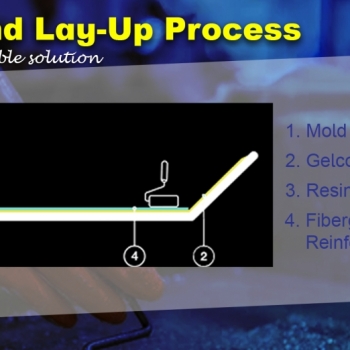

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

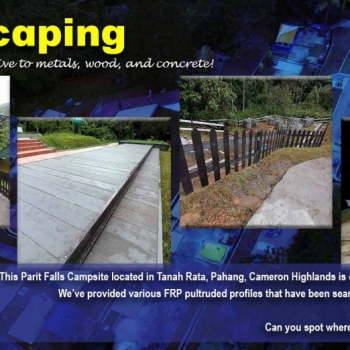

Transform DIY Projects with FRP Pultruded Profiles

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.