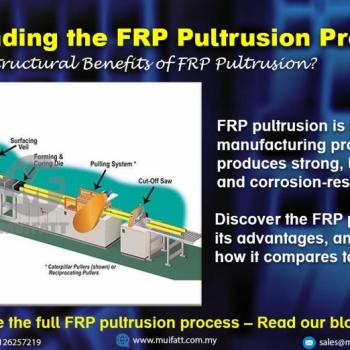

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

Transform DIY Projects with FRP Pultruded Profiles

04 Nov 2024

FRP Pultruded Profiles: DIY Ideas & Projects

- Key Takeaways

- Why Choose FRP Pultruded Profiles for DIY?

- DIY Landscaping Projects with FRP Pultruded Profiles

- Materials and Tools Checklist

- Eco-Benefits of FRP Pultruded Profiles

- Maintenance Tips for Long-Lasting FRP Structures

- Real-Life Application: A Case Study - Parit Falls Campsite

- Additional Use Cases Beyond Landscaping

- Choosing the Right FRP Profile

- Frequently Asked Questions (FAQs)

- How easy is it to work with FRP pultruded profiles?

- What tools do I need to work with FRP for DIY projects?

- How durable are our FRP pultruded profiles, and how long can you expect them to last in Malaysia's climate?

- Is FRP safe for outdoor use in extreme weather conditions?

- Are FRP profiles environmentally friendly?

- Can I paint or customize FRP pultruded profiles?

- Where can I purchase Mui Fatt FRP pultruded profile?

Key Takeaways

- FRP Pultruded Profiles: A durable, low-maintenance, and eco-friendly alternative for DIY landscaping and outdoor projects, providing enhanced resistance to weather, rot, and corrosion.

- DIY Project Ideas: Suitable for a wide range of applications, from garden edging and planters to decking, fences, and even large industrial uses.

- Materials & Tool Checklist: An essential list of FRP profiles and recommended tools for your DIY project, ensuring safety and efficiency in setup and assembly.

- Eco-Benefits: FRP has a low environmental footprint, requiring less energy to produce and offering long-term durability, which reduces waste.

- Maintenance Tips: Minimal upkeep is required! Just routine cleaning and periodic inspections will keep your FRP installations in great condition.

- Successful Applications: FRP profiles were used to create functional and aesthetic structures at Parit Falls Campsite, including gazebos, decking, fencing, and trellises.

- Beyond Landscaping: FRP pultruded profiles are also ideal for industrial uses, including cooling towers, wastewater plants, and coastal structures.

FRP (Fiberglass-reinforced Plastic) pultruded profiles offer a durable, low-maintenance alternative to traditional materials like wood, metal, and concrete. Ideal for landscaping and various DIY projects, FRP profiles provide excellent strength, longevity, and ease of use. Whether you're enhancing your garden, constructing a deck, or building a gazebo, FRP ensures long-lasting and low-maintenance solutions for your outdoor spaces.

Why Choose FRP Pultruded Profiles for DIY?

FRP pultruded profiles have gained popularity for DIY landscaping and construction projects due to their exceptional durability, lightweight nature, and ease of installation.

Key Benefits of FRP for DIY Enthusiasts

These profiles are perfect for both indoor and outdoor applications, with advantages such as:

-

Weather & Corrosion Resistance: Resists moisture, UV exposure, rot, and chemical degradation.

-

Lightweight & Easy to Install: Simplifies transportation and handling, ideal for DIY setups.

-

High Strength-to-Weight Ratio: Offers superior structural integrity without adding bulk.

-

Low Maintenance: Requires minimal upkeep after installation.

-

Eco-Friendly: Offers a sustainable alternative to heavier, more resource-intensive materials like steel and concrete.

Comparing FRP with Traditional DIY Materials

When choosing materials for DIY landscaping or construction, it’s essential to consider factors like durability, ease of maintenance, and environmental impact. The table below compares FRP pultruded profiles with wood, metal, and concrete.

| Feature | FRP Pultruded Profiles | Wood | Metal | Concrete |

| Durability | High resistance to corrosion, moisture, and chemicals | Prone to rotting and termite damage | Susceptible to rust and corrosion | Strong but prone to cracking |

| Maintenance | Minimal—occasional cleaning | High—requires sealing, painting, and repairs | Moderate—needs anti-corrosion treatments | Moderate—requires sealing and repairs |

| Weight | Lightweight and easy to handle | Light but weakens over time | Heavy and requires specialized tools | Very heavy, challenging to transport and install |

| Weather Resistance | UV-resistant, does not warp or degrade | Can warp and crack under harsh weather conditions | Can expand or contract with temperature changes | Weather-resistant but may erode over time |

| Installation | Easy to cut, drill, and assemble with standard tools | Requires woodworking tools and expertise | Requires welding and specialized tools | Needs heavy machinery and professional installation |

| Eco-Friendliness | Long lifespan, minimal waste, recyclable | Biodegradable but needs frequent replacement | Recyclable but energy-intensive to produce | Energy-intensive to produce, hard to recycle |

As illustrated, FRP pultruded profiles excel in durability, ease of installation, and maintenance, making them an ideal choice for DIY projects.

DIY Landscaping Projects with FRP Pultruded Profiles

Small-Scale Projects: Easy and Rewarding

-

Garden edging: Create neat and durable borders for your flower beds using FRP profiles.

-

Trellises and arbors: Build attractive supports for climbing plants.

-

Planter boxes: Construct stylish and long-lasting, rot-resistant planter boxes.

-

Pergolas: Create shaded walkways or seating areas.

Larger Projects: Ambitious and Achievable

-

Decking for patios or walkways: Build a durable and attractive outdoor deck, slip-resistant, weatherproof flooring for all seasons.

-

Fencing for gardens or property lines: Create a secure and aesthetically pleasing perimeter.

-

Gazebos and carports: Construct a functional and attractive structure for shade or shelter.

Materials and Tools Checklist

Before diving into your FRP DIY project, make sure you have the right materials and tools on hand. Working with FRP profiles is straightforward and typically requires only basic tools. Here’s a checklist to get you started:

-

Materials Needed: FRP pultruded profiles (e.g., I-beams, flat bars, hollow squares, c-channels, solid rods, deckings), screws, bolts, adhesives for assembly.

-

Essential Tools: Power drill, measuring tape, saw (carbide-tipped blade recommended), clamps, screwdriver, sandpaper.

-

Safety Gear: Safety goggles, dust mask, hearing protection, and gloves (FRP fibers can be sharp when cut).

With these basics, you’re ready to take on a range of projects with FRP! These profiles are easy to cut and assemble, making them accessible even for first-time DIYers.

Eco-Benefits of FRP Pultruded Profiles

Using FRP pultruded profiles in DIY projects is not only practical but also environmentally conscious. Here’s why:

-

Reduced Carbon Footprint: FRP production requires less energy than traditional materials like steel or concrete, resulting in a lower carbon footprint.

-

Long-Lasting Durability: FRP profiles resist rot, corrosion, and pest damage, meaning fewer replacements over time. This longevity reduces material waste and maintenance-related energy use.

-

Low Maintenance: Because FRP is highly resistant to weathering, it requires little upkeep, minimizing the use of cleaning products and coatings that could otherwise impact the environment.

Choosing FRP means you’re investing in sustainable materials that contribute to a cleaner, greener future.

Maintenance Tips for Long-Lasting FRP Structures

One of the many advantages of FRP pultruded profiles is their low maintenance needs. However, a few simple tips can help maximize the lifespan of your DIY projects:

-

Routine Cleaning: Occasionally clean FRP surfaces with mild soap and water to remove dust or grime. Avoid harsh chemicals that could affect the material’s surface.

-

Inspect Connections: Periodically check bolts, screws, or other fastenings, especially on structures like decks or gazebos, to ensure they’re secure.

-

Reapply Coating (Optional): If your project is highly exposed to direct sunlight or extreme weather, consider applying a UV-protective coating to preserve color and surface finish over the years.

These minor steps ensure your FRP projects stay in top condition, ready to withstand years of outdoor use.

Real-Life Application: A Case Study - Parit Falls Campsite

At Parit Falls, Cameron Highlands, FRP pultruded profiles and FRP customized flat sheets were used in creating durable, aesthetic outdoor structures for the campsite. These included decking, fencing, trellises, and a gazebo, all of which offer long-term durability and low maintenance and were seamlessly integrated into the site's landscaping.

Read the full case study here: Enhancing Parit Falls Campsite with FRP Structures

Additional Use Cases Beyond Landscaping

FRP pultruded profiles are incredibly versatile, with applications extending well beyond landscaping. In industrial environments, their high strength and corrosion resistance make them perfect for:

-

Cooling Towers: FRP’s corrosion resistance makes it ideal for cooling tower walkways and structural supports, where exposure to water and chemicals is common.

-

Wastewater Treatment Plants: Non-corrosive and durable, FRP is frequently used in walkways, grating, and support structures within wastewater treatment facilities.

-

Chemical Storage Facilities: The high strength and chemical resistance of FRP profiles make them a safe choice for supports and barriers in environments with chemical exposure.

-

Marine and Coastal Applications: FRP’s resilience against saltwater makes it perfect for coastal fencing, boardwalks, and docking structures.

These innovative uses in industrial applications highlight the unique properties of fiberglass pultruded profiles and FRP grating components, making them suitable for both DIY enthusiasts and industrial engineers. Their adaptability ensures they meet the requirements of various projects, from structural shapes to custom FRP structures.

Choosing the Right FRP Profile

Selecting the appropriate FRP profile depends on your project's specific needs. Consider factors like load-bearing requirements, desired aesthetic, and ease of installation. Our website offers a comprehensive range of fiberglass profiles and high-quality composite materials to suit various applications.

Frequently Asked Questions (FAQs)

How easy is it to work with FRP pultruded profiles?

FRP profiles, including pultruded fiberglass profiles, are relatively easy to work with, requiring basic tools and techniques.

What tools do I need to work with FRP for DIY projects?

Basic tools include a power drill, measuring tape, carbide-tipped saw, and fasteners. Standard safety gear is also recommended.

How durable are our FRP pultruded profiles, and how long can you expect them to last in Malaysia's climate?

Our FRP pultruded profiles, crafted from high-quality composite materials, are built to last 20-30 years or more, even in Malaysia's humid and sun-intensive climate. They resist corrosion, UV damage, and impact, making them ideal for outdoor use, outperforming wood (which can rot) and metal (which rusts). FRP requires minimal maintenance—just occasional cleaning and inspections—while providing strength and stability. Their superior durability ensures reliable, long-term performance in demanding environments.

Is FRP safe for outdoor use in extreme weather conditions?

Absolutely! FRP is UV-resistant, non-corrosive, and withstands extreme temperatures, making it ideal for outdoor applications.

Are FRP profiles environmentally friendly?

FRP, or fiberglass-reinforced plastic, is a sustainable material that requires less energy to produce than traditional structural materials like steel or concrete.

Can I paint or customize FRP pultruded profiles?

Yes, FRP can be painted using epoxy-based coatings, though it comes in various colors, reducing the need for painting.

Where can I purchase Mui Fatt FRP pultruded profile?

You can purchase our high-quality FRP pultruded profiles directly from our website, or by contacting our Sales Team via WhatsApp or email at sales@muifatt.com.my, or through our authorized distributors.

#FRPpultrudedprofiles #DIYFRPprojects #FRPdecking #FRPfencing #fiberglassstructures #durableconstructionmaterials #weatherresistantDIY

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

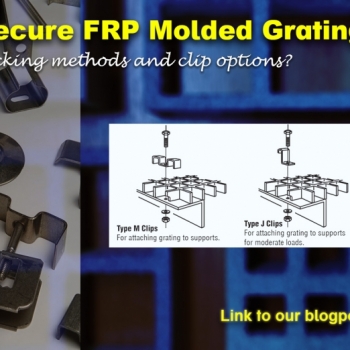

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

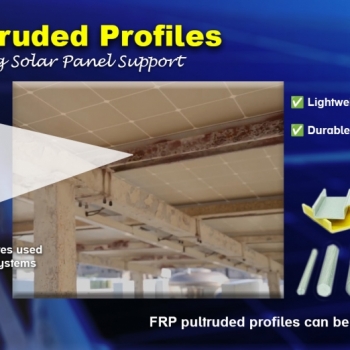

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

Essential Guidelines for Water & Septic Tanks in Borneo

Understand the regulations and guidelines for water and septic tanks in Borneo, plus compliance with SPAN, IWK, and SIRIM standards in Malaysia.

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

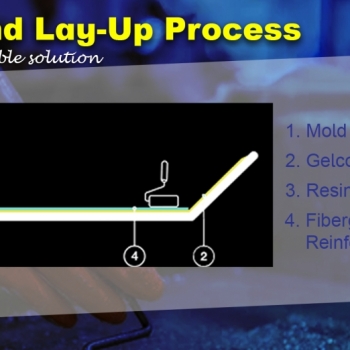

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.