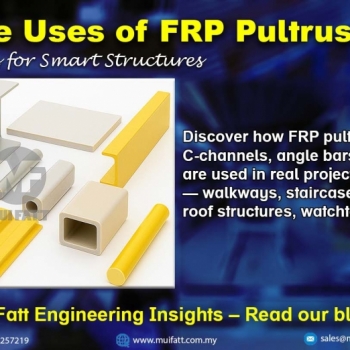

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

19 Nov 2024

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, and Sustainability

- Key Takeaways

- Introduction

- What is the FRP Hand Lay-Up Manufacturing Process?

- Beyond Hand Lay-Up: Exploring Other FRP Manufacturing Methods

- Why Choose the Hand Lay-Up Process?

- Is the Hand Lay-Up Process Sustainable?

- Aligning with Your Project Needs

- Successful OEM Products by Mui Fatt

- Frequently Asked Questions (FAQs)

Key Takeaways

- Versatile FRP Process: The FRP hand lay-up process is a hands-on manufacturing technique that allows for highly customizable, low-volume production of fiberglass-reinforced plastic components, ideal for projects requiring intricate designs and precise control over product properties.

- Steps Involved: The process includes mold preparation, fiberglass placement, resin application, reinforcement, curing, and demolding to create durable, high-quality products used in industries like automotive, architecture, and wastewater management.

- Sustainability: The hand lay-up process aligns with sustainable practices by consuming less energy, producing minimal waste, and creating long-lasting products that reduce the need for frequent replacements.

- Cost-Effective: Compared to other methods, the hand lay-up process is more affordable for custom or small-batch productions, making it a great option for startups and projects with budget constraints.

- Wide Applications: From custom water tanks and architectural elements to automotive parts, the hand lay-up process can be adapted to a variety of industries, delivering high-quality, tailored FRP solutions.

Introduction

We've all seen them – the strong, lightweight components used in everything from boats and airplanes to water tanks and architectural structures. These versatile materials are Fiberglass Reinforced Plastics, or FRP for short. Here at Mui Fatt, we've been working with FRP for over 40 years and are passionate about its potential.

However, there are various methods for creating these incredible composites within the world of FRP manufacturing. Today, we want to delve into one of the most fundamental and versatile techniques: the FRP hand lay-up process.

If you're looking for a way to create custom, high-quality FRP products, then the hand lay-up process might be the perfect fit for your needs. In this article, we'll explore the following:

-

What the hand lay-up process entails.

-

How it compares to other FRP manufacturing methods.

-

Why this process remains significant and sustainable for today's projects.

-

Realizing the value of this method and how you can leverage this method for your specific project needs.

What is the FRP Hand Lay-Up Manufacturing Process?

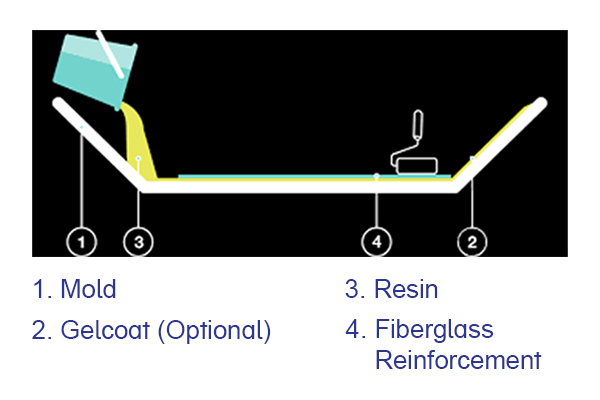

The FRP Hand Lay-Up Process, as the name suggests, involves a hands-on approach to creating composite parts, particularly through the composite layup process. This technique allows for a high degree of customization, making it ideal for unique designs and low-volume production runs. Here are the key steps in the fabrication process that ensure the quality composites are achieved.

-

Mold Preparation: We start by prepping the mold with a release agent to ensure easy removal of the finished product. Additionally, a gel coat can be applied to create a smooth and glossy surface finish.

-

Fiberglass Placement: Next comes the reinforcement material – fiberglass! We strategically lay sheets or mats of fiberglass into the mold, ensuring proper coverage and alignment with the desired shape.

-

Resin Application: The magic happens here. We meticulously apply liquid resin over the fiberglass, using brushes or rollers to achieve a thorough and even coat. This resin acts as the glue that binds the fibers together, creating the composite strength.

-

Reinforcement: Depending on the desired strength and thickness of the final product, we might add additional layers of fiberglass and resin. This allows for precise control over the final properties of the FRP component.

-

Curing: Once the layup is complete, it's time for the curing process. This can often be achieved at room temperature, although some applications might require controlled heat environments. During curing, the resin hardens and bonds with the fiberglass, solidifying the entire structure.

-

Demolding and Finishing: After the curing is complete, we carefully remove the FRP product from the mold. Depending on the project, there might be some final touches like trimming or polishing to achieve the desired finish.

This hands-on approach enables the creation of a wide variety of composite products, including structural parts and specialized applications. The method is commonly used for low-volume, high-complexity products, showcasing its versatility in the composite manufacturing industry.

-

Custom tanks (water tanks, chemical tanks, etc.)

-

Automotive components

-

Architectural design elements

-

And much more!

This method is commonly used for low-volume, high-complexity products.

Beyond Hand Lay-Up: Exploring Other FRP Manufacturing Methods

While the hand layup method offers incredible flexibility in the composite manufacturing industry, it's not the only option in the FRP world. Here's a quick look at some other commonly used composite processing techniques.

Pultrusion Process

-

How it works: Continuous reinforcement fibers are pulled through resin and shaped in a heated die.

-

Applications: High-volume production of profiles like rods, beams, and gratings.

-

Benefits: Precise shapes and high strength-to-weight ratio.

Filament Winding

-

How it works: Continuous filaments are wound over a rotating mandrel and coated with resin.

-

Applications: Cylindrical structures like pipes and tanks.

-

Benefits: Exceptional strength for pressure-bearing applications.

Resin Transfer Molding (RTM)

-

How it works: Fibers are placed in a mold, and resin is injected under pressure.

-

Applications: Automotive panels and large structures.

-

Benefits: Smooth surfaces and fast production.

Contact Molding

-

How it works: A flexible mold is placed on the desired shape, and resin-impregnated fibers are applied manually.

-

Applications: Complex shapes, one-off productions, and repairs.

-

Benefits: Suitable for intricate designs and small-scale production.

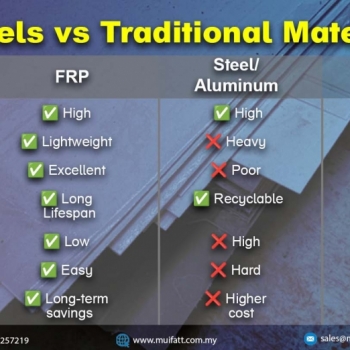

| Method | Advantages | Disadvantages | Applications |

| Hand Lay-Up | Simple, versatile, low-cost | Labor-intensive, inconsistent thickness | Custom parts, small-scale production |

| Contact Molding | Flexible, suitable for complex shapes | Requires skilled labor, potential for imperfections | One-off productions, repairs |

| Pultrusion | High-volume production, precise shapes | Limited design flexibility | Structural components, profiles |

| Filament Winding | High strength-to-weight ratio, precise control | Complex tooling, limited shape options | Cylindrical structures, pressure vessels |

| Resin Transfer Molding (RTM) | High-quality finish, consistent properties | Tooling costs, complex setup | Automotive parts, aerospace components |

Why Choose the Hand Lay-Up Process?

Despite the existence of advanced composite manufacturing techniques, the hand layup method remains a valuable tool for several reasons. For example, in our OEM projects, this fabrication process allows us to produce tailored FRP products such as water tanks, wastewater tanks, sewage systems, and fish ponds that meet specific client requirements with precision.

-

Customization: The beauty of hand lay-up lies in its versatility. We can easily adapt the process to create unique, intricate designs with varying dimensions, making it perfect for one-off projects or those requiring specific shapes.

-

Cost-Effectiveness: Compared to other methods requiring specialized equipment and high-volume production, hand lay-up is a cost-effective option for low-volume projects. The low initial investment in tooling makes it an attractive choice for startups or projects with limited budgets.

-

Flexibility: The hand lay-up process offers a high degree of flexibility, allowing for easy incorporation of design modifications.

Is the Hand Lay-Up Process Sustainable?

In today's world, sustainability in manufacturing is a growing concern. We're proud to say that the hand lay-up process aligns well with sustainable manufacturing principles. Here's why:

-

Low Energy Consumption: No high-temperature ovens or large-scale machinery are needed.

-

Minimal Waste: Precise material usage reduces scrap.

-

Durability: The durable nature of FRP products created through the hand lay-up process contributes to their longevity. This means fewer replacements and a reduced demand for new materials.

However, it's important to acknowledge that the use of chemical resins can pose environmental concerns. That's why we're constantly exploring and adopting newer, eco-friendly materials to minimize our footprint.

Aligning with Your Project Needs

Understanding the differences between FRP manufacturing methods helps you select the right one for your project. If your project demands:

-

High customization

-

Small production runs

-

Versatile designs

Then the hand lay-up process is likely your best fit. At Mui Fatt, we have over 40 years of expertise in creating custom FRP products tailored to your specific requirements.

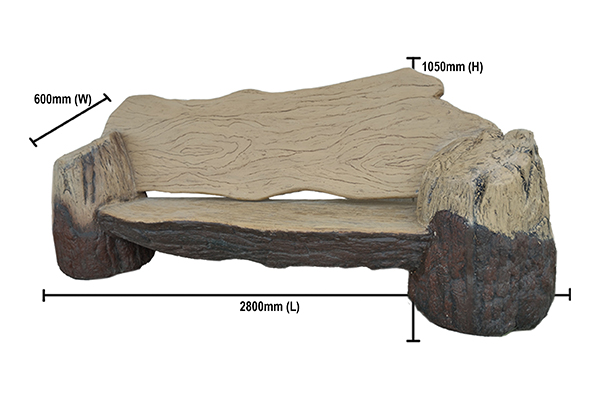

Successful OEM Products by Mui Fatt

We’ve successfully delivered a wide range of FRP customizable products for various industries, including:

-

Wastewater Treatment Tanks

-

Landscape (Planter Pot, Fish Ponds, Fences, Gazebo, Trellises, Pergola, Bench, etc.)

-

Pedestrian Walkway Structure and Roof

-

Road Sign/Signage Board

-

Handrailing

-

Laundry Trolley

-

Wastebin/Recycle Bin

-

MyKiosk

-

Custom gratings for industrial facilities

Ready to take your project to the next level? Contact us today via WhatsApp or email at sales@muifatt.com.my to discuss how we can leverage the hand lay-up process to bring your vision to life. Let's work together to create durable, sustainable, and high-quality FRP solutions.

Frequently Asked Questions (FAQs)

What is the FRP hand lay-up process best used for?

The FRP hand lay-up process is ideal for custom, low-volume products such as water tanks, architectural elements, and customizable products/components.

How does the hand lay-up process compare to other FRP methods?

The hand layup method is particularly effective for custom and intricate designs, while techniques such as pultrusion or RTM excel in high-volume production of composite parts.

Is the FRP hand lay-up process sustainable?

Yes, the composite layup process is energy-efficient and produces minimal waste, though advancements in eco-friendly resin systems can enhance its sustainability further.

Why should I choose Mui Fatt for FRP products?

With over 40 years of experience, we specialize in delivering tailored FRP solutions backed by certifications and a strong commitment to quality.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

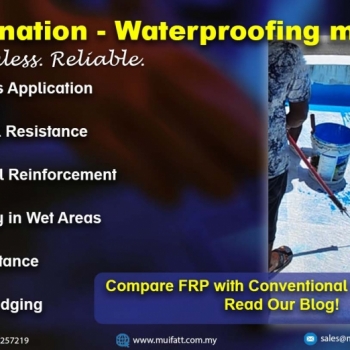

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

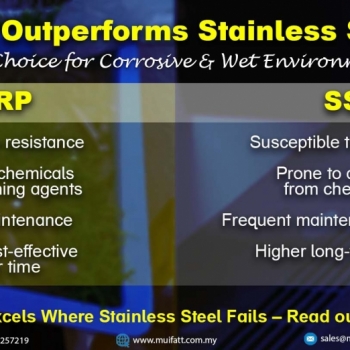

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

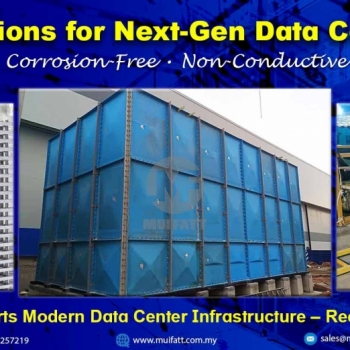

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.