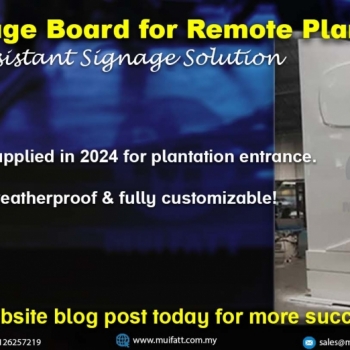

In 2024, Mui Fatt successfully fabricated and delivered 20 large-size fiberglass-reinforced plastic (FRP) signage boards for use as plantation entrance stands. Designed for high durability, weather resistance, and customization, these signage boards can be adapted for factory and plant usage across industries.

FRP Lamination for Mild Steel Equipment, Chemical Plant

02 May 2025

-

Client: Yinpolin Agriculture Sdn Bhd (now Hextar Fert Sdn Bhd)

Client: Yinpolin Agriculture Sdn Bhd (now Hextar Fert Sdn Bhd) -

Start Year: 2013 – Ongoing

-

Application: FRP clear coating on mild steel I-Beams, chemical tanks, handrails, and equipment supports

-

Method: Hand lay-up fiberglass lamination using clear resin + fiberglass mat

-

Purpose: Protect against chemical corrosion, increase structural lifespan, and reduce steel replacement frequency

Back in 2013, Yinpolin Agriculture Sdn Bhd approached us with a recurring issue—corrosion on their steel components due to aggressive chemical exposure in their fertilizer production plant. To address this, we proposed FRP lamination using clear resin and fiberglass matting. Over the years, our FRP application has proven effective in forming a seamless corrosion barrier, increasing the service life of their steel handrails, I-beams, and chemical tanks. Today, as Hextar Fert Sdn Bhd, they continue to trust our solutions to maintain safety and integrity in harsh environments.

Why FRP Lamination is Ideal for Chemical Fertilizer Plants

Corrosion Resistance for Aggressive Environments

Steel exposed to acidic or alkaline chemicals is prone to rapid rusting. FRP offers superior chemical resistance and does not degrade easily.

Long-Term Durability and Cost Efficiency

Instead of frequent steel replacements, our FRP lining extends asset lifespan by up to 3X with minimal maintenance.

Customizable for Irregular Structures

With hand lay-up lamination, even oddly shaped steel structures—like pipe joints, flange edges, or welded connections—can be fully coated.

Our Hand Lay-Up FRP Lining Process

-

Surface Preparation: Grit blasting and degreasing mild steel surface

-

Base Resin Application: High-quality clear polyester resin

-

Matting & Lamination: 1–3 layers of fiberglass mat laminated manually

-

Final Curing: Ensures structural bonding and chemical resistance

-

Post-Coating Inspection: Quality control and customer verification

Our long-term supply relationship with Hextar Fert showcases our commitment to quality and service consistency. We've supported plant expansion, shutdown maintenance, and even emergency repair coating services over the years. Our skilled team can work within tight downtime limits, ensuring zero compromise on plant operation.

Need corrosion protection for your chemical or steel structures? Explore our FRP Lamination & Lining Solutions or talk to us via WhatsApp or email at sales@muifatt.com.my for consultation.

Frequently Asked Questions (FAQs)

What makes FRP lamination better than paint coating?

Paints provide superficial protection, while FRP forms a reinforced barrier that resists chemicals and physical impact.

Can FRP lamination be applied on-site?

Yes, we perform on-site FRP coating even for confined or elevated areas using scaffolding and safety-certified crews.

How long does a typical FRP lamination last?

With proper application and maintenance, FRP lining can last for years in aggressive industrial conditions.

#FRPlamination #steelprotection #fiberglasscoating #chemicaltanklining #FRPMalaysia

Disclaimer:-

The content on this site is for general information and entertainment purposes and does not constitute legal counsel. We strive to keep our information as accurate as possible. However, we make no warranties about the completeness, accuracy, reliability, suitability, or availability with respect to the information contained on this page. You should rely on this information at your own risk. This website may include links to other third-party sites. These links are provided as a convenience to you as a reader, user, or browser only. We make no representation, warranty, or guarantee, nor do we endorse or take responsibility for any of the content of such sites.

Stay in touch with us if you’re interested in hearing from us promptly.

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Long-Term FRP Lining Solution for Fertilizer Equipment

Since 2013, Mui Fatt has delivered long-term corrosion protection for Ancom Crop Care’s fertilizer factory. Our grey-colored FRP lining has been applied to various mild steel structures, such as handrails, I-beams, and chemical tanks, to enhance durability in chemically aggressive environments.

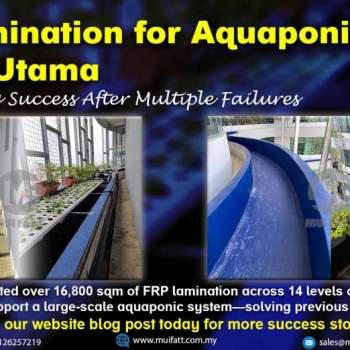

FRP Lamination for Aquaponic System at Bandar Utama

In 2022, Mui Fatt delivered a full-scale FRP lamination solution across 14 levels of a 28-storey building in Bandar Utama to support a commercial aquaponic system. Covering over 16,800 sqm, the project was completed within 3 months and successfully resolved persistent waterproofing issues that had previously failed using other methods. This project underscores the reliability of our FRP solutions in demanding, high-rise environments.

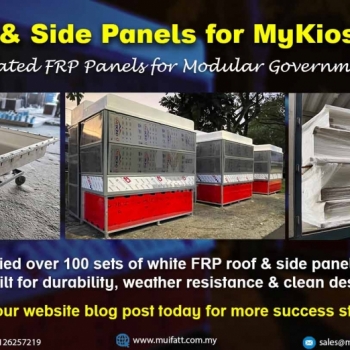

MyKiosk Project: FRP Roof and Side Panels Supplied to Local Councils

In August 2023, we successfully fabricated and delivered over 100 sets of FRP top roof and side panels to a third-party assembler of MyKiosk structures. These kiosks were distributed to various local district councils across Malaysia, showcasing the versatility and strength of FRP in public infrastructure.

FRP Seating & Planter Box for Tasek Central Courtyard

In early 2025, Mui Fatt supplied a range of FRP custom-made seating and planter boxes to Tasek Central Shopping Mall for the newly designed outdoor landscaping at Tuta Courtyard. Fabricated using the hand lay-up method with a textured concrete-look finish, these pieces offer aesthetic appeal and long-term durability for the mall’s public space.

FRP Portable Water Tanks Delivered to NURA, 2023

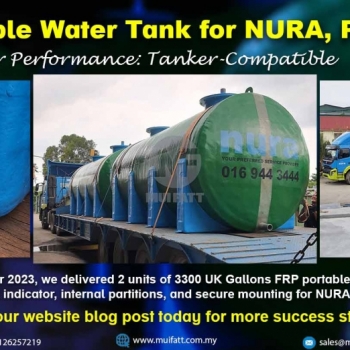

In December 2023, Mui Fatt successfully delivered 2 units of 3300 UK Gallons FRP Portable Water Tanks for NURA. The tanks were manufactured via filament winding, featuring transparent water level indicators, internal partitions, and secure mounts for mobile use. Custom-designed for water tanker compatibility, these units fulfill strict project specifications.

FRP High-Rise Urinal Stand Supplied to NURA

In 2015, Mui Fatt proudly supplied 65 units of FRP high-rise standing urinals to NURA. These units were specifically engineered for temporary construction sites and high-rise structures, providing a hygienic and time-saving sanitation solution for workers. The durable fiberglass construction, combined with portability and cost-efficiency, made it an ideal choice for challenging site conditions.

Custom FRP Kiddie Carts for Aeon Mall – 2012 Project Highlight

In 2012, Mui Fatt proudly supplied 50 units of custom-designed FRP kiddie carts for Aeon Shopping Mall. Engineered for durability and child-friendly use, these vibrant red trolleys were modeled after cartoon-themed trains and featured integrated seating for young shoppers. With a sturdy FRP body and steel basket, the carts enhanced both safety and shopping convenience for families—demonstrating how functional design can also bring joy and engagement to retail experiences.