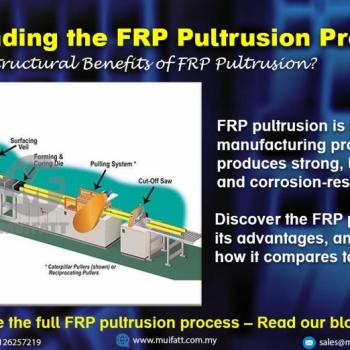

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

Exploring the Versatility of Fiberglass-Reinforced Plastic (FRP) in Swimming Pools and Water Theme Parks

20 Jun 2023

General Application of Fiberglass-Reinforced Plastic (FRP) in Swimming Pools or Water Theme Parks

FRP, a composite material consisting of a polymer matrix reinforced with fiberglass, is renowned for its exceptional strength, durability, and corrosion resistance. These qualities have made it a sought-after choice for numerous applications, including the construction of swimming pool decorative structures. In this article, we will delve into the widespread use of FRP in swimming pool environments, with a specific focus on its application in decorative structures and sculptures. Additionally, we will highlight the advantages of utilizing FRP and address the common challenges encountered.

Swimming pool decorative structures encompass a wide array of components that enhance the aesthetic appeal of the pool area. Notably, these structures are typically made from FRP due to its remarkable ability to withstand the harsh pool environment, including exposure to water, chemicals, and UV radiation. The robustness of FRP makes it an ideal material for:

Pool Water Features

FRP is often used to create water features such as decorative fountains, cascades, or waterfalls. These structures can be designed in various shapes and sizes, adding a visually pleasing element to the pool area.

Pool Edging and Coping

FRP can be utilized for pool edging and coping, which are the materials placed around the perimeter of the pool. FRP copings are available in different designs and colours, providing an attractive border while also serving as a functional edge for the pool.

Pool Gratings and Drains

FRP gratings and drains are used to cover the pool’s overflow channels or drainage systems. These components are corrosion-resistant, lightweight, and offer good drainage capabilities. They are available in various styles to complement the pool design.

Decorative Pool Panels

FRP panels can be used to create decorative features on the pool walls, adding texture and visual interest. These panels are available in different patterns, colours, and finishes, allowing for customization and creativity.

Pool Sculptures and Artwork

FRP is often used as a medium for creating artistic sculptures and artwork within swimming pools. The material’s versatility allows for intricate designs and shapes, making it a suitable choice for creating unique and eye-catching pieces.

Introduction to FRP Sculpture

FRP sculpture, also known as fiberglass-reinforced plastic sculpture, is a fascinating form of art that involves the use of special materials to create stunning and durable structures.

The remarkable features for FRP sculpture includes:

-

Highly resistant to weathering, corrosion, and fading

-

Suitable for outdoor installations in public spaces, gardens, aquatic facilities, and more, FRP sculpture and FRP statue options are perfect for adding artistic elements to any environment.

-

Allows for larger and more intricate designs

-

FRP sculpture and FRP statue can take on a wide range of shapes and forms.

-

Lightweight for easier transportation and installation

-

The non-porous surface of FRP sculpture and FRP statue prevents the growth of mold or mildew.

-

Low-maintenance and long-lasting

-

Adds beauty and creativity to urban landscapes

-

Easily transported and displayed without compromising integrity

Dive into the Depths: Why FRP Sculptures are a Splash in Swimming Pools and Water Theme Parks

FRP sculptures are a common sight in swimming pools and water theme parks, appearing in various forms and sizes, ranging from small decorative elements to large, intricate installations. These sculptures can portray aquatic creatures, plants, abstract shapes, or themed designs that align with the overall concept of the swimming pool or water theme park. The popularity of FRP as a material choice for creating sculptures and artwork in these aquatic environments stems from its exceptional durability, weather resistance, and ability to withstand exposure to water and chemicals. However, one paramount reason for selecting FRP is Safety, as no business owner wants any unfortunate incidents to occur within their premises.

To enhance safety in wet environments, FRP sculptures can be designed with a non-slip surface texture. This feature significantly reduces the risk of slipping or falling when swimmers or visitors come into contact with the sculptures. Moreover, FRP sculptures can be manufactured with smooth and rounded edges, minimizing the potential for injuries. Unlike materials like concrete or metal, which may have sharp edges or rough surfaces, FRP can be crafted to be safer and more user-friendly.

Another advantage of FRP is its lightweight nature compared to materials like stone or metal. This characteristic makes it less likely to cause significant harm if accidentally bumped into or tipped over. It not only reduces the risk of injuries caused by heavy or unwieldy sculptures in the pool area but also makes them easier to install, reposition, or replace if needed.

Furthermore, FRP is non-corrosive, meaning it does not rust or degrade over time when exposed to water and pool chemicals. Additionally, FRP is non-toxic, ensuring that it does not leach harmful substances into the pool water. These features contribute to a safer and healthier swimming environment.

FRP exhibits good impact resistance, allowing it to withstand accidental impacts or collisions without shattering or creating sharp fragments. This property further enhances safety by reducing the likelihood of injury in case of accidental contact with the sculptures.

Moreover, FRP is an electrical insulator, which is particularly important in swimming pool environments where electrical safety is a concern. The use of FRP sculptures helps to prevent the risk of electrical shock.

In summary, the versatility of FRP sculptures not only provides an opportunity for designers and artists to create a safer environment for swimmers and visitors but also allows for visually stunning and engaging elements within swimming pools and water theme parks. Additionally, FRP sculptures offer a cost-effective alternative to sculptures made from other materials, such as bronze or stone. With its balance between affordability and durability, FRP has become a popular choice for water-themed attractions.

Creating Custom-Made Fiberglass Sculptures with Precision

Skilled artisans, who are highly trained and experienced in the art of sculpture, utilize molds and advanced techniques to meticulously create custom-made fiberglass sculptures.

Fiberglass Reinforced Plastic (FRP) is a material that offers remarkable versatility, enabling artisans to reproduce intricate details and bring complex designs to life with astonishing accuracy in the final sculpture. This means that even the most delicate features, such as fine lines, curves, and textures, can be faithfully replicated in the finished piece. The manufacturing process of FRP sculptures involves a series of carefully executed steps to guarantee exceptional quality and meet the specific requirements of each client.

Firstly, a detailed design or concept is developed in collaboration with the client, ensuring that their vision is accurately captured. Once the design is finalized, skilled artisans create a mold that will serve as the foundation for the sculpture. Using this mold as a guide, layers of fiberglass cloth are carefully laid out and saturated with resin. The resin acts as a binding agent, holding the layers together and providing strength and durability to the sculpture. This meticulous process allows for the creation of a solid and stable structure that can withstand various environmental conditions.

After the initial layers are set, additional layers may be added to enhance the strength and thickness of the sculpture if desired. Skilled artisans pay close attention to every detail during this stage, ensuring that each layer is applied evenly and smoothly to achieve a flawless finish. Once all the layers have been applied, the sculpture is left to cure and harden. This curing process allows the resin to fully set and ensures that the sculpture retains its shape and structural integrity. After curing, any imperfections or rough edges are carefully sanded down and polished to create a smooth surface.

Finally, skilled artisans meticulously paint and finish the sculpture using high-quality paints and coatings specifically designed for FRP. This step enhances the overall aesthetic appeal of the sculpture while also providing protection against UV rays and other environmental factors that could potentially damage the artwork.

Challenges in FRP Pool Sculptures and Our Ways to address them as a Manufacturer

When it comes to FRP pool sculptures, there are some common challenges that can arise. Here are a few of them, along with our approaches as manufacturers to address these issues:

Fading and Discoloration

Over time, prolonged exposure to sunlight and pool chemicals can cause the vibrant colours and finishes of FRP sculptures to dull or change, affecting their aesthetic appeal. To combat this, we use only high-quality FRP materials specifically designed for outdoor and aquatic environments. These materials incorporate UV-resistant additives and pigments to minimize fading. Regular maintenance, including periodic repainting or refinishing, may also be necessary to preserve the sculptures visual appeal.

Over time, prolonged exposure to sunlight and pool chemicals can cause the vibrant colours and finishes of FRP sculptures to dull or change, affecting their aesthetic appeal. To combat this, we use only high-quality FRP materials specifically designed for outdoor and aquatic environments. These materials incorporate UV-resistant additives and pigments to minimize fading. Regular maintenance, including periodic repainting or refinishing, may also be necessary to preserve the sculptures visual appeal.

Impact Damage

Another challenge is impact damage. Although FRP is impact-resistant, it can still be susceptible to damage when subjected to significant impact or force. Accidental collisions, vandalism, or rough treatment can result in chipping, cracking, or breakage of the sculptures. To address this, we ensure that our sculptures are structurally sound and engineered to withstand the specific demands of the pool environment. Careful installation, placement in low-risk areas, and appropriate signage to discourage climbing or rough handling can help minimize this issue.

Environmental Stress Cracking or Fiberglass Gelcoat Crazing

FRP sculptures can develop cracks when exposed to excessive stress from factors such as temperature changes, humidity, or chemical exposure. To mitigate this problem, we prioritize proper material selection and design considerations. Thorough engineering analysis and testing are conducted to ensure the sculptures structural integrity and resilience against environmental stress. Regular inspections can also help identify and address any issues related to stress cracking.

FRP sculptures can develop cracks when exposed to excessive stress from factors such as temperature changes, humidity, or chemical exposure. To mitigate this problem, we prioritize proper material selection and design considerations. Thorough engineering analysis and testing are conducted to ensure the sculptures structural integrity and resilience against environmental stress. Regular inspections can also help identify and address any issues related to stress cracking.

Delamination

Delamination is yet another challenge that can occur in FRP sculptures. It refers to the separation or detachment of the layers of the composite material. Delamination can be caused by inadequate bonding during manufacturing, moisture infiltration, or exposure to harsh environmental conditions. To prevent this, we adhere to proper fabrication techniques and implement stringent quality control measures. Regular inspections are recommended to business owner to help prevent or identify delamination issues.

Maintenance and Cleaning

Pool sculptures require regular maintenance and cleaning to keep them in good condition. Routine cleaning using appropriate methods and gentle cleaning agents helps preserve their aesthetic appeal. Pool chemicals, mineral deposits, algae, and other contaminants can accumulate on the surface of the sculptures, affecting their appearance. However, FRP is generally less susceptible to mold or algae growth due to its non-porous nature and smooth surface. Additionally, our FRP sculptures are often coated with gelcoat1 as protective layer, which further inhibits algae growth.

Pool sculptures require regular maintenance and cleaning to keep them in good condition. Routine cleaning using appropriate methods and gentle cleaning agents helps preserve their aesthetic appeal. Pool chemicals, mineral deposits, algae, and other contaminants can accumulate on the surface of the sculptures, affecting their appearance. However, FRP is generally less susceptible to mold or algae growth due to its non-porous nature and smooth surface. Additionally, our FRP sculptures are often coated with gelcoat1 as protective layer, which further inhibits algae growth.

Installation and Anchoring

Proper installation and anchoring are vital to ensure stability and safety of FRP sculptures in the pool area. Inadequate anchoring or unstable mounting can lead to sculptures toppling over, potentially causing injuries or damage. We provide manufacturer guidelines and professional assistance when needed to ensure proper installation and anchoring practises.

While these challenges exist, they can be mitigated or managed through proper design, material selection, installation practices, regular maintenance, and periodic inspections. Our teams are equipped to help overcome these potential issues and ensure the longevity and safety of FRP sculptures in swimming pools. We pride ourselves on providing high-quality materials, customization option, artistic expertise, and engineering support, setting us apart in the industry.

Talk to us for your project today! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – FRP Garden Landscape

References:

- Gelcoat – a specialized coating applied to the surface of FRP products, plays a crucial role in protecting FRP products. It provides surface protection, UV resistance, corrosion resistance, waterproofing, and aesthetic enhancement. It acts as a barrier, shielding the FRP from environmental elements and preventing damage caused by UV radiation, moisture, chemicals, and abrasion. It also offers impact resistance and makes FRP products easier to clean and maintain.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

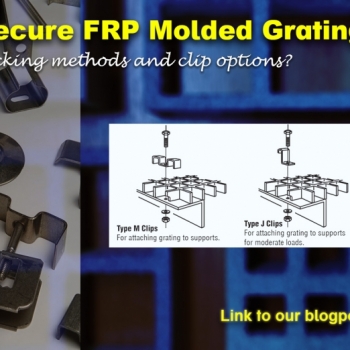

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

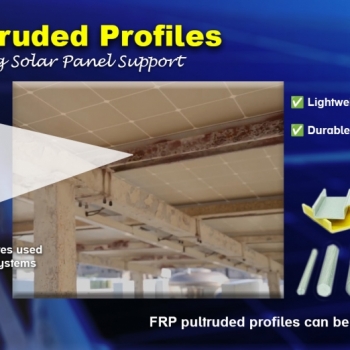

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

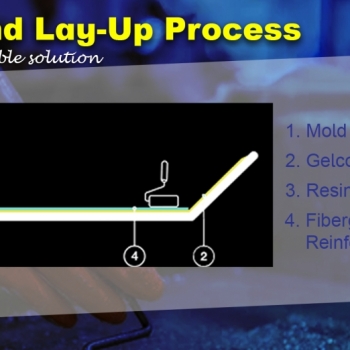

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

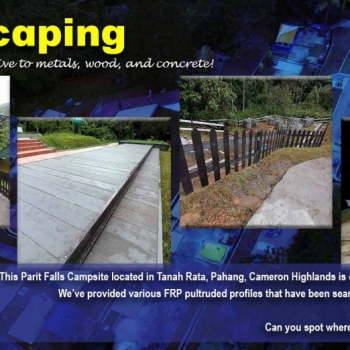

Transform DIY Projects with FRP Pultruded Profiles

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.