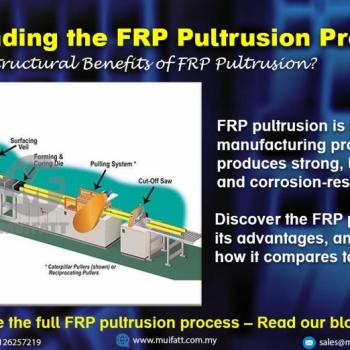

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

Trench Covers: Upgrade Your Construction Site with High-Quality Trench Covers for the Utmost Safety, Durability, and Peace of Mind

26 Jun 2023

Did you know that there's a hidden network beneath the ground that powers our modern world? It's made up of cables that carry electricity to our homes and businesses. But have you ever thought about how these cables are protected? That's where trench covers come in. They're like plates that cover the cables and keep them safe. Whether it's a construction site or a utility area, these covers make sure everyone stays safe and follows the rules. They come in different sizes and can handle different amounts of weight, so they're used in lots of different places. So let's take a closer look at these trench covers and see how they keep us safe while we use electricity every day.

Benefits of Using Trench Covers:

Enhances worker safety

Safety is important. Trench covers help keep workers safe by preventing falls and injuries. They provide a strong barrier to avoid accidents in construction sites, road repairs, and other situations with open trenches. Workers and employers can feel confident with trench covers.

Without trench covers, workers must be cautious around open trenches to avoid accidents. This slows down work and increases the risk of injuries. Trench covers eliminate these hazards, allowing workers to focus on their tasks without worry.

Protects underground utilities

Trench covers protect important underground utilities like water pipes, electrical cables, and gas lines. Damage or tampering with these utilities can cause big problems for communities.

Trench covers prevent damage from heavy equipment and vehicles driving over open trenches. They also stop unauthorized access to utility lines, avoiding dangerous situations and service interruptions.

Improves aesthetics

Open trenches and pits are not visually appealing. They disrupt the area's look and can be an eyesore. But trench covers solve this problem.

Trench covers make trenches look better by hiding them beneath the ground and creating a smooth surface. They are useful when there is construction or maintenance happening in a city or residential area. They improve the way things look.

Reduces the risk of liability claims

Accidents can happen, and when they do, they can lead to expensive claims. Open trenches without precautions can be dangerous and cause injuries or damage. But by using trench covers, the risk of these incidents is greatly reduced.

Trench covers keep workers safe by preventing accidents in open trenches. They also protect businesses from legal and financial troubles. Companies show their dedication to safety by using trench covers, which reduce the risk of accidents and costly lawsuits.

Increases efficiency

Efficiency is important in construction and maintenance projects. Trench covers help improve efficiency by providing easy access for maintenance or repairs. Instead of wasting time and effort on removing debris or securing temporary barriers, trench covers offer a convenient solution for working on underground utilities.

Trench covers help workers access areas quickly and without obstacles. This saves time and ensures efficient completion of maintenance or repair tasks. Trench covers also increase productivity and make the project flow smoother.

Types and Materials of Trench Covers:

There are various types available to suit different needs. These include solid covers, and grated covers.

Solid covers are exactly what their name suggests - they are solid plates that cover the trench. They provide a flat surface for people to walk on and offer excellent protection against falls or accidents. Solid covers are commonly made from materials such as steel, reinforced concrete, or fiberglass-reinforced plastic (FRP).

Grated covers have holes in them that let air flow through the trenches. This is important for electrical cables that get hot when they're used. The air circulation helps cool the cables down and keeps them working well for a long time.

Steel: Durability and Strength

Steel is a popular material for trench covers because it is very strong and durable. It can handle heavy loads without bending or breaking, so it works well for busy places like roads and construction sites.

Steel is a popular material for trench covers because it is very strong and durable. It can handle heavy loads without bending or breaking, so it works well for busy places like roads and construction sites.

Steel trench covers are made from galvanized steel, which is coated with zinc to prevent rust and corrosion. This makes the cover strong and durable, even in tough weather or chemical exposure.

Steel trench covers are not only strong, but they also offer great fire resistance. This makes them perfect for areas with electrical installations or underground utility access points that require fire safety.

Fiberglass-Reinforced Plastic (FRP): Lightweight Yet Robust

Fiberglass-reinforced plastic (FRP) trench covers offer a unique combination of lightweight design and robustness. They are made by reinforcing plastic with fine fibers of glass, resulting in a material that is strong and durable.

Fiberglass-reinforced plastic (FRP) trench covers offer a unique combination of lightweight design and robustness. They are made by reinforcing plastic with fine fibers of glass, resulting in a material that is strong and durable.

One of the main advantages of FRP trench covers is their lightweight nature. This makes them easy to handle and install, reducing the risk of injury for workers during the installation process. Despite their light weight, FRP covers can still support heavy loads without cracking or deforming.

FRP trench covers also have excellent resistance to chemicals, making them suitable for use in environments where exposure to corrosive substances is common. They do not rust or corrode like metal covers, ensuring long-lasting performance even in harsh conditions.

Precast Concrete: Standardized and Durable

Precast concrete is a popular construction material known for its durability and consistency. It is made by pouring concrete into molds and letting it cure before being taken to the construction site.

Precast concrete is a popular construction material known for its durability and consistency. It is made by pouring concrete into molds and letting it cure before being taken to the construction site.

Precast concrete is advantageous because it is made in controlled environments, ensuring consistent quality and strength. This means that each piece, like trench covers, meets specific standards and can handle heavy loads and tough weather.

Exploring Fiberglass-Reinforced Plastic (FRP) for Trench Covers:

High Strength-to-Weight Ratio

One of the top considerations is the strength-to-weight ratio. In this regard, fiberglass-reinforced plastic (FRP) stands out as an excellent option. FRP offers a remarkable combination of strength and lightness, making it an ideal choice for applications where weight is a concern.

FRP trench covers are better than materials like precast concrete or steel because they are strong but not heavy. This makes them easy to install and maintain. They are great for any project, big or small, because they are durable and portable.

Corrosion Resistance in Harsh Environments

FRP trench covers are great in tough environments where corrosion is a big problem for materials like steel or concrete. FRP is super resistant to corrosion from chemicals, moisture, saltwater, and extreme temperatures. This means the trench covers stay strong even when faced with harsh conditions for a long time.

By choosing FRP trench covers instead of steel or precast concrete, you can make your infrastructure last longer and reduce maintenance expenses. FRP is not affected by rust or chemical damage, making it perfect for industries like petrochemical plants, wastewater treatment facilities, and coastal areas with corrosive elements.

Non-Conductive Material for Electrical Safety

In some applications where safety is important, using non-conductive materials is necessary. Fiberglass-reinforced plastic (FRP) trench covers are a good choice for electrical applications because they do not conduct electricity, making them safer than metal options like steel.

Using FRP trench covers in electrical infrastructure projects can help reduce hazards. FRP is non-conductive, so there is no risk of electric shock or short circuits from live wires. This makes FRP a great choice for industries like telecommunications, utilities, and transportation where electrical safety is important.

Low Maintenance Requirements

FRP trench covers are better than precast concrete concrete or steel. They need less maintenance because they don't corrode or get damaged by chemicals or extreme temperatures.

FRP trench covers are more durable and require less maintenance compared to steel or precast concrete ones. This means you can save money on repairs and replacements. With FRP trench covers, you can focus on your main tasks without worrying about constant upkeep.

Customizable Options for Project Needs

Fiberglass-reinforced plastic (FRP) trench covers are great because they can be customized to fit different project needs. You can choose the size, load rating, color coding, and even have custom logos on the cover. Other types of trench covers like precast concrete or steel may not offer as many customization options.

Customized FRP trench covers allow you to meet specifications and look good. You can customize them to meet industry standards and add branding.

Understanding the Key Differences between Trench Covers, Trench Plates, and Pedestrian Walk Boards: Ensuring Safety in Open Trenches

|

|

|||

|

Purpose |

Cover and secure trenches |

Cover and bridge trenches |

Temporary walkways/platforms |

|

Load Capacity |

Designed for pedestrians |

Designed for vehicles |

Designed for pedestrians/workers |

|

Material |

Durable materials like metal, precast concrete or composite materials |

Heavy-duty steel or other strong metals |

Wood or metal |

|

Weight |

Relatively lighter |

Heavier |

Moderate |

|

Usage |

Prevent falls, provide safe walking surface over trenches |

Temporarily bridge trenches for vehicles and equipment |

Create temporary elevated walkways/platforms for workers |

|

Typical Application |

Construction sites, road works, utility installations |

Construction sites, utility works |

Construction sites, maintenance activities |

|

Safety Features |

Prevent unauthorized access, reduce the risk of accidents or falls |

Distribute weight, provide stability for vehicles and equipment |

Provide stable walking surface, prevent slipping or accidents |

|

Placement |

Placed directly over trenches or excavations |

Positioned to bridge the entire width of the trench |

Placed on scaffolding or supports |

|

Load-Bearing Capacity |

Designed for pedestrian traffic only |

Designed to support heavy vehicles and equipment |

Designed for pedestrians and light equipment |

|

Installation |

Usually lighter and easier to handle and install |

Heavier and may require mechanical equipment for placement |

Generally straightforward installation process |

Understanding Trench Plates and Pedestrian Walk Boards:

Temporary Coverings for Construction Work

Trench plates, also called road plates or trenwa, are used during construction to cover open trenches and make them safe for pedestrians and vehicles. They provide a stable surface for people to walk or drive on around the construction site.

Safe Passage with Pedestrian Walk Boards

Pedestrian walk boards are important for safe passage over open trenches. They are designed to provide a secure platform for people to cross without any risks. Whether its workers or passers-by, these walk boards prevent accidents and injuries.

Load Ratings for Trench Plates and Walk Boards

Trench plates and walk boards have different load ratings for different needs. Load ratings show the maximum weight they can handle safely. Contractors can pick from various load ratings to find the best fit for their project. They consider things like traffic, equipment, and soil conditions.

Meeting Industry Standards for Safety and Stability

Trench plates and walk boards are made to be safe and sturdy. They are built with strong materials that can handle heavy weights and stay strong. These coverings go through strict tests to make sure they follow safety rules. Contractors can feel confident using trench plates and walk boards that meet industry standards because they create a safe place for workers and pedestrians.

Versatile Applications of Pedestrian Walk Boards and Trench Plates

Temporary Access for Various Purposes

Pedestrian walk boards and trench plates are versatile products used in various applications, like roadworks, utility maintenance, and event setups. They provide temporary access across excavations or open trenches, ensuring the safety and convenience of pedestrians on construction sites.

Trench covers are strong platforms used in roadworks to keep people safe from falling into open trenches. They are designed to handle pedestrian traffic and are used when roads or pavements are being dug up. These covers provide a secure path over the excavations, allowing people to move around without any problems and minimizing disruptions.

Safe Passage across Construction Sites

Pedestrian walk boards and trench plates help people safely cross construction sites. They are like ramps that bridge gaps made by excavations or trenches. These products provide stability, so pedestrians can walk on uneven ground without worry. They make sure workers and visitors can move through construction zones safely.

These systems are made to handle lots of people walking on them without breaking. They are designed to be strong and safe, so they can hold the weight of many people at once. This helps prevent accidents from happening when people walk on uneven ground.

Urban and Rural Applications

Pedestrian walk boards and trench plates are useful in both cities and countryside. In cities, they help keep pedestrians safe during roadworks and utility maintenance, while also keeping traffic flowing smoothly. They allow cities to make necessary infrastructure improvements without causing problems for people or vehicles.

In rural areas, trench covers help with agricultural and construction work. They provide temporary access solutions for tasks like accessing irrigation channels or creating pathways in fields. These covers are versatile and make it easier to work in challenging terrains.

Maximizing the Benefits of Pedestrian Walk Boards and Trench Plates:

Regular Inspections: Ensuring Proper Installation and Stability

Regular inspections are important for pedestrian walk boards and trench plates. They make sure these safety measures are installed correctly and provide stability for workers.

Inspectors must check the placement of walk boards and trench plates to ensure they are correctly positioned over the trench. This involves looking for gaps or misalignment that could be dangerous for people walking or working on them.

Inspectors must check the strength of walk boards and trench plates. These safety devices should be able to handle the weight they will carry without bending or breaking. Regular inspections help find any problems early, so they can be fixed or replaced quickly.

Appropriate Sizing: Matching Trench Dimensions and Load Requirements

Choosing the right walk boards and trench plates is important. They should fit the trench and support the weight properly. The safety devices need to cover the whole trench and give workers a safe surface to walk on.

Not matching the dimensions can lead to uncovered areas where people might accidentally step into an open trench, causing serious injuries. Using small walk boards or plates can also increase the risk of the structure failing.

When choosing safety measures, consider the load requirements. Pick walk boards or trench plates that can handle the weight of the traffic. Following sizing guidelines reduces risks and keeps workers safe.

Proper Storage and Handling: Preventing Damage or Accidents

Storing walk boards and trench plates properly is important to keep them in good condition. They should be kept in a specific area to protect them from harm when they are not being used.

To avoid accidents, it's important to handle walk boards and trench plates carefully. Mishandling can weaken them or make them fall, putting workers at risk. Workers should be trained on the right way to move and position these safety measures to reduce the chance of accidents.

Regular Cleaning: Removing Debris or Slippery Substances

Regularly cleaning walk boards and trench plates is important to keep the work environment safe. Debris like dirt, leaves, or construction materials can build up and make it slippery for workers.

To clean safety devices, remove debris from gaps in walk boards and around trench plates. Promptly address slippery substances like oil or grease. Regular cleaning prevents accidents caused by reduced traction on these surfaces.

Educating Workers: Safety Protocols When Using Walk Boards or Plates

It's important to teach workers about safety rules for using walk boards or plates. Training helps them use these safety measures correctly and lowers the chance of accidents happening.

Workers need to know weight limits and not go over them when using walk boards or plates. They also need to know how to place their feet properly to stay balanced when crossing trenches.

Workers should be trained to recognize signs of wear or damage on walk boards and trench plates during inspections. This helps them report issues quickly for repairs before accidents happen.

Factors to Consider When Choosing Trench Covers:

Load Capacity Requirements Based on Anticipated Traffic or Equipment

When choosing a trench cover, the load capacity is crucial. It must be able to handle the weight of expected traffic or equipment. If the cover can't handle the load, accidents, property damage, and expensive repairs can occur.

When figuring out how much weight a cover can handle, think about the heaviest things that will be on it, like machinery, vehicles, or people. Also, remember to consider how the weight might be spread out. For example, if there will be lots of heavy trucks driving over the cover often, it needs to handle more weight than if it's just for people walking.

Consider future changes in your operations that may affect load requirements. If there might be more traffic or heavier equipment in the future, choose a trench cover with a higher load capacity than what you need now. This way, you won't have to replace the covers earlier than expected.

Dimensions of the Trench to Ensure Proper Fit

Choosing trench covers that fit properly is important for safety and preventing accidents. Before buying, measure and assess the dimensions of your trench. The opening and frame should match the covers you choose.

A trench cover that doesn't fit well can be dangerous. It can cause tripping or become unstable. To make sure it fits properly, use tools like tape measures or laser distance meters to measure both the inside and outside dimensions accurately. Also, consider any irregularities in shape or size in different parts of the trench.

Not all trenches are the same size. Some trenches may be wider or deeper at different points. In these cases, adjustable or modular trench covers can be used to fit the irregularities. These covers are flexible, making installation and removal easier while still providing a secure fit.

Material Durability for Long-Term Use in Specific Environments

Trench covers need to be durable to last a long time, especially in certain environments. Different materials have different levels of resistance to things like weather, chemicals, and heavy use. Picking the right material ensures that your trench covers will last and work well in that environment.

For outdoor use, choose materials like HDPE, FRP, or galvanized steel. They resist corrosion, UV radiation, and extreme temperatures. HDPE is light but strong, good for pedestrian areas with light vehicle traffic. FRP is very strong and can handle heavy-duty applications. Galvanized steel is very durable and can handle heavy loads without rusting or degrading.

In some industries or places with chemical spills, you may need trench covers that can resist chemical corrosion. Materials like stainless steel or composite polymers (FRP) are designed for this purpose. Consider the needs of your environment to pick the right material for your trench covers.

Cost-Effectiveness Considering Lifespan and Maintenance Needs

When choosing trench covers, it's important to think about the overall cost, not just the upfront price. Cheaper options might seem good at first, but they could end up costing more in the long run due to maintenance or replacements.

Determine how long trench covers will last based on their materials and quality. Covers made from strong materials and built well usually last longer than cheaper ones that wear out fast in tough conditions.

Different types of trench covers have different maintenance requirements. Some materials need to be regularly cleaned, painted, or coated to keep them strong and looking good. This extra maintenance can take a lot of time and money.

Investing in better trench covers can save you money in the long run because they last longer and require less maintenance.

Making Informed Decisions for Trench Cover Solutions:

Evaluate project-specific needs before selecting a cover type.

Before making any decisions, it's important to think about what your project needs. Is the trench cover for a temporary or permanent solution? Knowing this will help you choose the right cover type.

When using temporary trench covers for construction sites or events, it's important to think about how long you'll need them. These covers are easy to put on and take off when you're done using them. They give workers and pedestrians a safe way to access underground utilities. If you have a long-term project, you might want to choose permanent trench covers instead. These products are stronger and last longer.

Consider potential risks, such as heavy traffic or extreme weather conditions.

To choose the right trench cover, consider the risks at your project site. Factors like traffic or bad weather can affect how well the cover works.

If heavy vehicles or machinery will pass over the trench cover a lot, choose a strong design that can handle heavy loads without sacrificing safety. Look for options with reinforced edges and high load-bearing capacities for lasting performance in busy areas.

Extreme weather can be a problem for trench covers. If your site gets lots of rain or freezing temperatures, get products that resist corrosion and have anti-slip properties. This will stop accidents from slippery surfaces and work well in bad weather.

Consult with experts or manufacturers for customized solutions.

When you have special project needs or difficult site conditions, talking to experts or manufacturers can help you design custom trench covers that fit your requirements. They know a lot about the industry and can help you with things like load requirements, access points, and installation methods.

Collaborating with experts helps you get trench covers made to your exact needs. They can make covers in non-standard sizes or with special features for unique site conditions. Customized solutions make sure the covers work well and are safe.

Balance cost considerations with long-term benefits.

Cost is important when choosing trench cover solutions, but it shouldn't be the only factor. You need to think about both upfront costs and long-term benefits before making a decision.

Think about the total cost of different covers. Some may cost more at first but last longer and need less fixing. Cheaper options could end up costing more in repairs or not be as safe.

Evaluate the return on investment by considering factors like how long it lasts, how easy it is to install and remove, how much maintenance it needs, and if it has a warranty. This will help you make a smart decision that matches your goals and budget.

Concluding Thoughts on Trench Covers:

In conclusion, trench covers are important for safety and efficiency in different industries and construction sites. By learning about the types and materials of trench covers, we now understand how versatile and durable they are. Trench covers have many benefits, like preventing accidents, protecting workers, and making operations run smoothly.

Fiberglass-Reinforced Plastic (FRP) is a strong, lightweight, and corrosion-resistant material. It can be used to make trench covers that last a long time and protect against tough environmental conditions.

Trench plates and pedestrian walk boards are important for safety. They can be used for temporary roads, protecting sidewalks, or covering excavations. Knowing the different options helps you pick the right one for your needs.

To get the most out of pedestrian walk boards and trench plates, think about load capacity, slip resistance, installation ease, and maintenance needs. By making smart choices based on these factors, you can ensure that your trench covers work well and last a long time.

To make smart decisions that balance safety, functionality, and cost, carefully evaluate your needs. Think about things like how much traffic there will be, how much weight the structure needs to support, what the weather is like, and how much money you have to spend.

Investing in good trench covers is smart. It makes things safer and more productive in different industries. You can choose traditional materials or try new ones like FRP. Knowing the benefits of each will help you find the right one for your needs.

Don't compromise on safety - explore our range of trench cover solutions today and ensure a secure working environment for your team. WhatsApp or email - sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – FRP Covers

FAQs:

What are the main types of trench covers available?

Trench covers come in various types, including solid steel plates, composite materials like FRP, and modular systems that allow for flexibility in size and shape.

How do trench covers benefit construction sites?

Trench covers provide a safe walking surface, prevent accidents or falls into excavations, protect utilities from damage, and enable smooth traffic flow around construction sites.

Can pedestrian walk boards be used in other applications besides construction?

Yes, pedestrian walk boards have versatile applications beyond construction. They can be utilized for temporary roadways during events or festivals, as well as providing safe pathways in industrial facilities or maintenance areas.

Are trench plates suitable for heavy equipment?

Trench covers are specifically engineered to bear substantial weights and provide support for heavy machinery like trucks and cranes. When choosing trench plates, it is crucial to consider factors such as the desired load capacity, the suitable thickness and size of the plate, as well as the appropriate materials to be used.

What factors should I consider when choosing trench covers?

When selecting trench covers, consider factors such as load capacity requirements, slip resistance properties, ease of installation and removal, weather resistance capabilities, and long-term

References:

- Trenches - Trenches are excavated channels or ditches in the ground, serving various purposes such as utility installations or drainage. They require proper planning, safety measures, and maintenance to ensure stability and mitigate risks. Trenches are commonly found in construction sites, road works, and utility projects.

- Trench Covers - Trench covers are protective covers used to secure and cover trenches, providing a safe walking surface for pedestrians. They are commonly used in construction sites and road works to prevent falls and accidents.

- Trench Plates - Trench plates are heavy-duty metal plates used to cover and bridge trenches, designed to support vehicles and heavy equipment. They are utilized in construction sites and utility works to create temporary roadways for safe passage.

- Pedestrian Walk Board - Pedestrian walk boars are temporary walkways or platforms at elevated heights, designed for pedestrians and workers. They are commonly used in construction sites and maintenance activities, providing stable walking surfaces in areas where regular access is limited.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

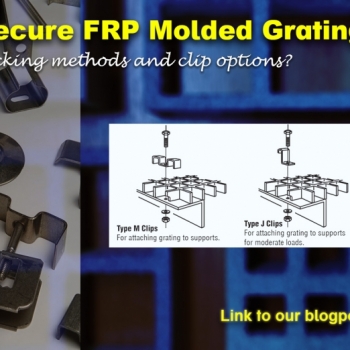

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

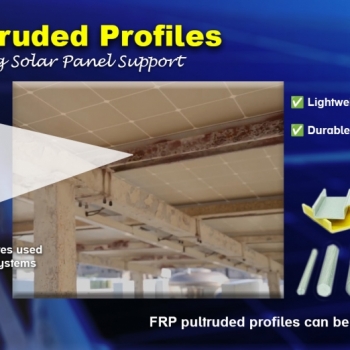

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

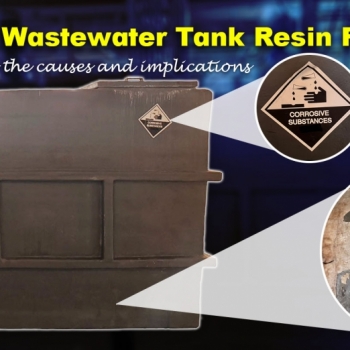

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

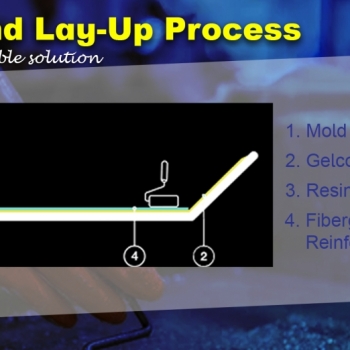

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

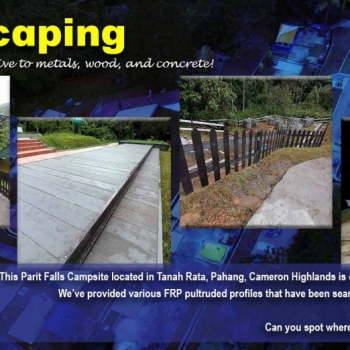

Transform DIY Projects with FRP Pultruded Profiles

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.