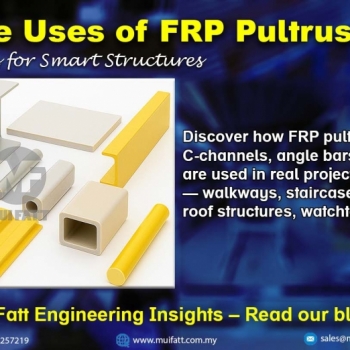

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

FRP Innovations in Wastewater Treatment Plant

29 Jul 2024

FRP in Wastewater Treatment: Innovative Solutions

FRP in Wastewater Treatment: Innovative Solutions

- Global Adoption of FRP in Wastewater Treatment

- United States:

- Canada:

- Australia:

- European Nations:

- Reasons for Global Adoption

- Case Study: Los Angeles County Sanitation Districts' Joint Water Pollution Control Plant (JWPCP)

- Conclusion

- Frequently Asked Questions

- What is Fiberglass-Reinforced Plastic (FRP)?

- Why is FRP preferred over traditional materials in wastewater treatment?

- How does FRP contribute to environmental sustainability?

- Are there any notable projects that have successfully implemented FRP in wastewater treatment?

- What are the advancements in FRP technology?

Global Adoption of FRP in Wastewater Treatment

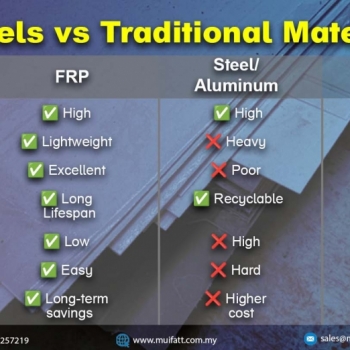

Fiberglass-Reinforced Plastic (FRP) has gained widespread acceptance and adoption in wastewater treatment facilities around the world, revolutionizing infrastructure design and operations. Several countries have embraced FRP technology for its numerous advantages over traditional materials, including superior corrosion resistance, durability, and cost-effectiveness.

Fiberglass-Reinforced Plastic (FRP) has gained widespread acceptance and adoption in wastewater treatment facilities around the world, revolutionizing infrastructure design and operations. Several countries have embraced FRP technology for its numerous advantages over traditional materials, including superior corrosion resistance, durability, and cost-effectiveness.

United States:

In the United States, FRP has become a cornerstone of modern wastewater treatment infrastructure. Municipalities and utilities across the country rely on FRP components such as pipes, tanks, and covers to withstand corrosive wastewater and harsh environmental conditions. The lightweight nature of FRP facilitates easier installation and maintenance, while its long-term durability ensures reliable operation and reduced lifecycle costs.

Canada:

Canadian wastewater treatment facilities have also embraced FRP technology to address corrosion challenges and enhance infrastructure resilience. FRP products are widely used in wastewater conveyance systems, treatment processes, and odor control structures. The ability of FRP to withstand extreme temperatures, chemicals, and environmental factors makes it a preferred choice for Canadian municipalities seeking sustainable, long-lasting solutions.

Australia:

In Australia, where water scarcity and environmental sustainability are top priorities, FRP plays a vital role in wastewater treatment and reuse initiatives. FRP pipes and tanks are utilized in desalination plants, sewage treatment facilities, and industrial wastewater treatment systems, offering corrosion resistance and reliability in challenging operating conditions. FRP components' lightweight and modular design facilitates rapid deployment and flexibility in infrastructure expansion projects.

European Nations:

Several European nations, including Germany, the Netherlands, and the United Kingdom, have embraced FRP technology to modernize aging wastewater treatment infrastructure and comply with stringent environmental regulations. FRP products are integral to the success of wastewater treatment plants, providing corrosion-resistant solutions for critical components such as clarifiers, aeration systems, and chemical storage tanks. FRP's durability and low maintenance requirements contribute to the long-term sustainability of wastewater treatment operations across Europe.

Reasons for Global Adoption

-

Corrosion Resistance

-

The primary driver behind the global adoption of FRP in wastewater treatment is its exceptional corrosion resistance. FRP products outperform traditional materials like steel and concrete in corrosive environments, reducing the risk of infrastructure failure and costly repairs.

-

-

Durability and Longevity

-

FRP offers superior durability and longevity compared to conventional materials, ensuring reliable performance over extended service lives. This reliability reduces downtime, maintenance costs, and lifecycle expenses for wastewater treatment facilities.

-

-

Environmental Sustainability

-

As countries prioritize environmental stewardship and resource conservation, FRP emerges as a sustainable solution for wastewater treatment infrastructure. Its recyclability, low environmental impact, and energy-efficient production processes align with sustainability goals and regulatory requirements.

-

-

Technological Advancements

-

Ongoing advancements in FRP manufacturing processes and product innovation have expanded the range of applications and performance capabilities of FRP in wastewater treatment. Advanced composite materials, coatings, and design techniques enhance the resilience and functionality of FRP products in demanding operating environments.

-

Case Study: Los Angeles County Sanitation Districts' Joint Water Pollution Control Plant (JWPCP)

The Los Angeles County Sanitation Districts' Joint Water Pollution Control Plant (JWPCP) in Carson, California, serves as a prime example of the successful implementation of FRP in large-scale wastewater treatment facilities. The plant, which treats an average of 275 million gallons of wastewater per day, incorporates FRP components such as pipes, tanks, and odor control covers. These FRP elements were chosen for their corrosion resistance, lightweight properties, and ease of maintenance. The usage of FRP has contributed to the plant's operational efficiency, longevity, and reduced environmental impact. This case study exemplifies how FRP technology can effectively address the challenges faced by modern wastewater treatment facilities. For more detailed information on the JWPCP, visit the Los Angeles County Sanitation Districts' official website.

Conclusion

The global adoption of FRP in wastewater treatment reflects its status as a versatile, reliable, and sustainable solution for addressing infrastructure challenges and advancing environmental objectives. By leveraging FRP technology, countries around the world can enhance the efficiency, resilience, and environmental performance of their wastewater treatment systems, ensuring safe water resources for future generations.

Frequently Asked Questions

What is Fiberglass-Reinforced Plastic (FRP)?

Fiberglass-Reinforced Plastic (FRP) is a composite material made of a polymer matrix reinforced with fibers, typically glass. It is known for its high strength, lightweight properties, and resistance to corrosion and environmental factors.

Why is FRP preferred over traditional materials in wastewater treatment?

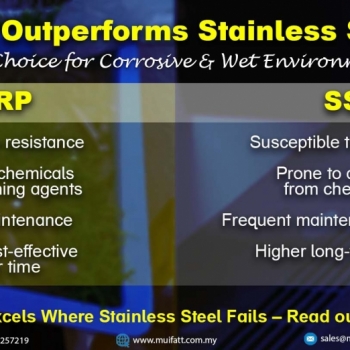

FRP is preferred due to its exceptional corrosion resistance, durability, and longevity. It outperforms traditional materials like steel and concrete in harsh and corrosive environments, reducing maintenance costs and extending the lifespan of infrastructure.

How does FRP contribute to environmental sustainability?

FRP is considered environmentally sustainable due to its durability, low maintenance requirements, and overall energy efficiency compared to traditional materials. Its high resistance to corrosion and harsh environmental conditions results in a longer lifespan, significantly reducing the need for frequent replacements. This durability translates to lower resource consumption over time.

Are there any notable projects that have successfully implemented FRP in wastewater treatment?

Yes, a notable project in the Los Angeles County Sanitation Districts' Joint Water Pollution Control Plant (JWPCP), which utilizes FRP for its superior corrosion resistance and durability. This project showcases the effectiveness of FRP in challenging environmental conditions.

What are the advancements in FRP technology?

Advancements in FRP technology include improved manufacturing processes, innovative composite materials, enhanced coatings, and advanced design techniques. These advancements have expanded FRP's applications and performance capabilities in wastewater treatment.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

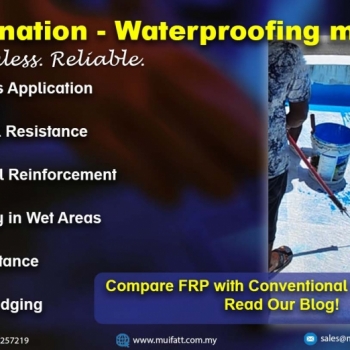

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

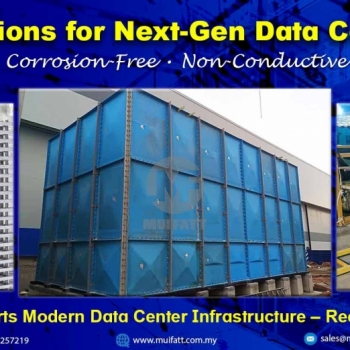

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.