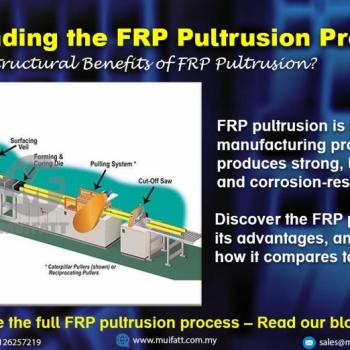

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

OEM Fiberglass Manufacturing at Mui Fatt: Durable & Reliable Solutions

21 May 2023

OEM Fiberglass Manufacturing

OEM Fiberglass Manufacturing

- Customize OEM Fiberglass Products with Mui Fatt - Leading Manufacturer in Malaysia

- What is Fiberglass?

- Manufacturing Techniques at Mui Fatt

- Explore Our OEM Fiberglass Product Range

- OEM Fiberglass Capabilities and Minimum Order Quantity

- Conclusion: Why Choose Mui Fatt for OEM Fiberglass Products?

- Frequently Asked Questions (FAQs)

- What are OEM fiberglass products?

- What types of fiberglass products does Mui Fatt manufacture?

- Why should I choose fiberglass over traditional materials like metal or wood?

- What are the main manufacturing techniques used at Mui Fatt for fiberglass products?

- What is the minimum order quantity (MOQ) for OEM fiberglass products at Mui Fatt?

Customize OEM Fiberglass Products with Mui Fatt - Leading Manufacturer in Malaysia

At Mui Fatt, we take pride in our manufacturing capabilities as one of Malaysia's leading manufacturers of OEM fiberglass products, offering custom solutions tailored to specific industrial needs. With over 40 years of experience in the field, we specialize in producing high-quality, durable, lightweight, and corrosion-resistant FRP products. Our deep understanding of composite materials and mastery of cutting-edge manufacturing techniques - such as pultrusion, hand layup, and filament winding - along with exceptional fiberglass cloth products, allow us to create custom solutions tailored to various industrial needs. We offer high-quality OEM products, composite products, and tailored solutions designed to meet the specific needs of industries, including construction, marine, automotive, and more.

What is Fiberglass?

Fiberglass is a composite material made from glass fibers combined with a resin matrix, resulting in a versatile, strong, and lightweight product. It is widely used in industries, such as construction, automotive, marine, and oil & gas due to its high durability and resistance to harsh environmental conditions like heat and corrosion.

How is Fiberglass Made?

The process of making fiberglass begins with melting silica sand and kaolin clay, which are then extruded into fine filaments. These filaments are woven into mats or fabrics and coated with resin to enhance their strength. The material is shaped using molds, and after curing, it forms a tough, durable composite that can withstand heavy-duty industrial applications. At Mui Fatt, we specialize in producing fiberglass products like tanks, gratings, and pipes using this process.

Manufacturing Techniques at Mui Fatt

To produce high-quality OEM fiberglass products, we apply several manufacturing techniques: pultrusion, hand layup, and filament winding, each with its strengths:

- Pultrusion: involves pulling continuous strands of glass fibers through a resin bath and shaping them using a heated die. This process ensures high-strength profiles with consistent quality, ideal for industries requiring durable and reliable parts. The pultrusion technique is perfect for producing structural profiles, gratings, and other products where consistent mechanical strength is essential.

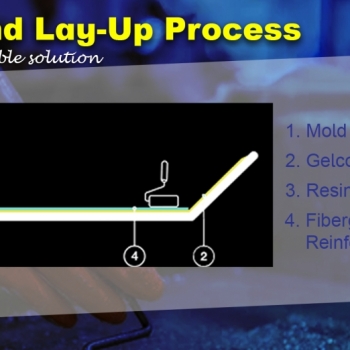

- Hand Layup: This technique involves manually layering glass fiber mats and applying resin by hand. It provides the flexibility to create customizable shapes, making it ideal for unique or low-volume products that need precision and craftmanship. For custom projects that require more complex shapes and designs, we use the hand layup method.

- Filament Winding: We also employ filament winding for creating strong composite structures by wrapping continuous fiber strands around a rotating mandrel. This method is highly effective for manufacturing cylindrical structures like tanks and pressure vessels that need superior strength and resistance to internal pressure.

Custom OEM Fiberglass Solutions for Your Industry

We understand that every project is unique, which is why we specialize in custom OEM fiberglass products. Whether you're looking for specialized components for industrial applications or need specific shapes and sizes, our team can work with you to design and manufacture fiberglass products that meet your exact specifications.

Advantages of Fiberglass in OEM

Fiberglass offers several advantages compared to traditional materials like wood, metal, or plastic:

- Lightweight and Strong: Fiberglass provides an excellent strength-to-weight ratio, making it ideal for industries where reducing weight without sacrificing strength is critical.

- Corrosion Resistance: Fiberglass performs exceptionally well in outdoor or corrosive environments, resisting damage from chemicals, moisture, and extreme temperatures.

- Durable and Long-Lasting: Due to its durability, fiberglass requires less maintenance and offers a longer service life compared to other materials.

- Customizable Shapes: Its malleability allows us to mold fiberglass into complex shapes, making it a highly versatile material for various applications.

These qualities make fiberglass an ideal solution for industrial applications that require a balance of strength, durability, and customization.

Explore Our OEM Fiberglass Product Range

We provide a comprehensive range of customizable fiberglass products to suit diverse applications. Our solutions are built to deliver strength and longevity in even the harshest environments. From custom pultruded profiles to filament-wound tanks and pipes, Mui Fatt provides various fiberglass products tailored to your requirements. The OEM process includes molding, laminating, and finishing, ensuring that the final product meets industry standards. Contact us today via WhatsApp or email at sales@muifatt.com.my to learn more about how our manufacturing techniques can help bring your project to life. These are a few examples of our OEM products:

- FRP Tanks - Designed for storing chemicals or fuel, these tanks offer superior corrosion resistance and can be customized to meet specific size and shape requirements. Ideal for water storage, chemical processing, and wastewater treatment applications.

- FRP Pipes - Known for their excellent strength-to-weight ratio and resistance to corrosion, fiberglass pipes are widely used in industrial applications like chemical processing and wastewater treatment.

- Gratings and Panels - Used in structural applications such as bridges, platforms, and walkways, offering slip resistance and durability.

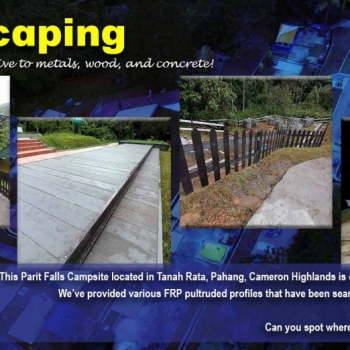

- Pultruded Profiles – Structural profiles designed for maximum strength and corrosion resistance. Including beams, channels, and handrails, offering high strength and resistance to environmental elements.

- Trench Covers – Reliable and sturdy covers for industrial or municipal infrastructure.

- Cable Trays and Ladders - Providing excellent electrical insulation and corrosion resistance, used in power plants and industrial facilities.

OEM Fiberglass Capabilities and Minimum Order Quantity

As an OEM fiberglass manufacturer, we are capable of producing custom fiberglass parts tailored to your specific design and technical requirements. Whether you need small, intricate components or large-scale products, our team is equipped to meet your needs.

Customization Options

We offer a range of customization options, including varying resin types (polyester, vinyl ester, etc.), fiber types (E-glass, S-glass), and finishing options to meet different environmental and performance needs. This flexibility ensures that your products will perform optimally, no matter the application.

Minimum Order Quantity (MOQ)

Our MOQ policy is designed to accommodate both large-scale industrial orders and smaller, custom projects. We work closely with our clients to ensure that their specific requirements are met without compromising on quality or lead times.

Conclusion: Why Choose Mui Fatt for OEM Fiberglass Products?

With over four decades of experience, Mui Fatt stands as a trusted fiberglass manufacturer in Malaysia. Our expertise in pultrusion, hand layup, and filament winding allows us to produce a wide variety of fiberglass products that cater to diverse industries.

We leverage our extensive expertise and advanced manufacturing techniques to deliver OEM fiberglass products tailored to your specifications. Here's why customers rely on us:

- Custom Solutions: We offer fully customized fiberglass solutions, that adapt to your project’s unique requirements.

- Durability & Strength: Our products are known for their superior strength-to-weight ratio, corrosion resistance, and long lifespan.

- Flexible Manufacturing: With techniques such as pultrusion and hand layup, we deliver precision-crafted products, regardless of complexity.

- Proven Expertise: Our team has extensive experience delivering OEM fiberglass products that meet the highest standards across various industries.

Our commitment to quality, customization, and client satisfaction ensures that we deliver solutions that exceed expectations. Whether you need high-strength structural profiles or corrosion-resistant gratings, Mui Fatt is your go-to partner for all things fiberglass.

Frequently Asked Questions (FAQs)

What are OEM fiberglass products?

OEM (Original Equipment Manufacturing) of fiberglass products refers to producing composite parts according to customer specifications. This includes design, molding, and fabrication of fiberglass-based components tailored to the specifications of individual customers.

What types of fiberglass products does Mui Fatt manufacture?

At Mui Fatt, we produce FRP gratings, structural profiles, water tanks, cable ladders, trays, and other custom fiberglass products to meet diverse industrial applications.

Why should I choose fiberglass over traditional materials like metal or wood?

Fiberglass offers several advantages such as being lightweight, corrosion-resistant, and durable. It is also cost-effective, long-lasting, and ideal for industries requiring tough, high-performance materials.

What are the main manufacturing techniques used at Mui Fatt for fiberglass products?

We use pultrusion, hand layup, and filament winding techniques, allowing us to offer precision-engineered fiberglass products with various shapes, sizes, and strengths.

What is the minimum order quantity (MOQ) for OEM fiberglass products at Mui Fatt?

We maintain flexibility with MOQ, catering to both large industrial projects and small, custom orders to ensure our clients' unique needs are met.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

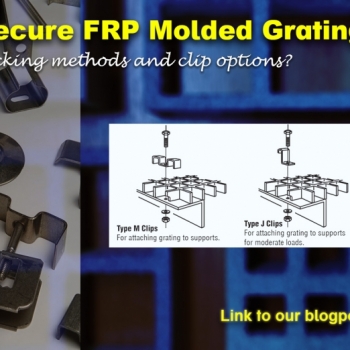

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

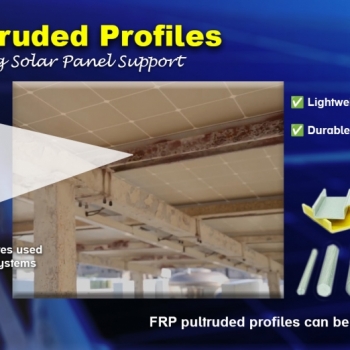

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

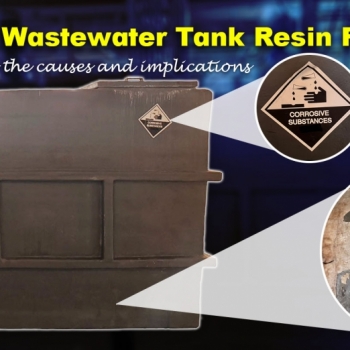

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

Transform DIY Projects with FRP Pultruded Profiles

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.