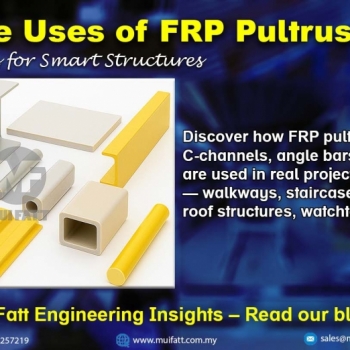

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Comparing FRP Handlay, SMC, and Pressed Steel Panel Tanks: Which Is Best for Your Needs?

28 Mar 2024

Panel Tank - A Comprehensive Guide to Choosing Between FRP Hand Lay-up, SMC, and Pressed Steel

Panel Tank - A Comprehensive Guide to Choosing Between FRP Hand Lay-up, SMC, and Pressed Steel

- Introduction: Selecting the Ideal Tank for Your Needs

- Understanding the Differences: Comparing Construction and Composition

- Comparison Table: A Quick Overview

- Durability and Maintenance Requirements: Ensuring Longevity and Performance

- Installation Techniques: Ensuring Proper Assembly

- Conclusion: Making an Informed Decision

- Frequently Asked Questions

Introduction: Selecting the Ideal Tank for Your Needs

Choosing the right type of tank for your industrial or commercial needs is crucial for ensuring optimal performance, durability, and cost-effectiveness. Among the various options available, FRP Hand Lay-up, SMC (Sheet Molding Compound), and Pressed Steel Panel Tanks stand out as popular choices due to their unique characteristics and suitability for different applications.

Understanding the Differences: Comparing Construction and Composition

Before diving into the comparison, it's essential to understand the fundamental differences between FRP Hand Lay-up, SMC, and Pressed Steel Panel Tanks.

FRP Hand Lay-up Tanks: Handcrafted Durability

FRP Hand Lay-up Panel Tanks are constructed through the hand application of fiberglass layers and resin, providing excellent corrosion resistance and versatility in various environments.

SMC Tanks: Molded for Strength

SMC Panel Tanks are made from a composite material consisting of fiberglass, resin, and filler, molded into smooth panels, offering high durability and resistance to corrosion, UV radiation, and chemical exposure.

Pressed Steel Tanks: Rugged Reliability

Pressed Steel Panel Tanks utilize corrugated steel panels for robustness and strength, making them suitable for applications requiring mechanical impact resistance.

Comparison Table: A Quick Overview

To facilitate a quick overview, here's a comparison table highlighting the key aspects of FRP Hand Lay-up, SMC, and Pressed Steel Panel Tanks:

| Aspect | FRP Hand Lay-up (Mui Fatt Panel Tank) | SMC (Sheet Molding Compound) | Pressed Steel Panel Tank |

| Surface | Hand-applied fiberglass layers, gelcoat applied to both side, single side smooth | Molded surface, both side smooth | Corrugated steel panels |

| Filler | Pure resin and fiberglass mixture | Filler, resin and fiberglass mixture | N/A |

| Pressure Test Standard | BS EN 13280:2001 | Typically follows industry standards (e.g., ASTM) | Typically follows industry standards (e.g., BS EN 13280, BS 1564:1975, SS22:1979) |

| Size Available |

0.5m x 0.5m |

1m x 1m |

1m x 1m |

| Number of Joints | Lesser | More | More |

| Durability | Highly durable, excellent corrosion resistance, resistant to rust, rot, UV, and chemical degradation | Highly durable, good resistance to corrosion, UV radiation, and chemical exposure, molded surface for added strength | Sturdy and robust, good durability and strength against mechanical impacts and external forces |

| Maintenance Requirements | Low maintenance, periodic inspections for integrity of fiberglass layers and resin | Low maintenance, regular inspections for cracks, delamination, or damage to the molded surface | May require more maintenance, including repainting to prevent corrosion, inspecting and repairing seals, addressing rust or coating issues |

| Installation Techniques | Site preparation, lamination, joint sealing | Site preparation, panel assembly, reinforcement and support | Site preparation, panel assembly, coating and protection |

| Professional Involvement | Recommended | Recommended | Recommended |

*Specific details may vary based on manufacturers, designs, or standards associated with each material type

Durability and Maintenance Requirements: Ensuring Longevity and Performance

Durability and maintenance play crucial roles in determining the longevity and performance of industrial tanks. Let's explore how each tank type fares in terms of durability and maintenance requirements:

FRP Hand Lay-up Tanks: Resilience Under Inspection

FRP Hand Lay-up Panel Tanks offer excellent corrosion resistance, making them durable in various environments. Their low maintenance requirements involve periodic inspections for the integrity of fiberglass layers and resin.

SMC Tanks: Strength in Regular Checks

SMC tanks boast high durability and resistance to corrosion, UV radiation, and chemical exposure. Regular inspections for cracks, delamination, or damage to the molded surface are necessary to maintain their performance.

Pressed Steel Tanks: Maintenance for Reliabililty

Pressed Steel Panel Tanks are known for their sturdy construction and robustness against mechanical impacts and external forces. However, they may require more maintenance, including repainting to prevent corrosion, inspecting and repairing seals, and addressing rust or coating issues.

Installation Techniques: Ensuring Proper Assembly

Proper installation is paramount for ensuring the structural integrity and performance of industrial tanks. Here's a brief overview of the installation techniques for each tank type:

FRP Hand Lay-up Tanks: Crafted with Precision

FRP Hand Lay-up Panel Tanks require site preparation, lamination of fiberglass layers, and proper joint sealing for structural integrity.

SMC Tanks: Assembled for Stability

SMC Panel Tanks involve site preparation, panel assembly, and reinforcement and support to maintain stability and structural integrity.

Pressed Steel Tanks: Assembled for Resilience

Pressed Steel Panel Tanks require site preparation, panel assembly, and coating and protection to enhance durability and prevent corrosion.

Conclusion: Making an Informed Decision

Choosing the right material type is a crucial decision that can impact the efficiency and longevity of industrial operations. By understanding the differences, durability, maintenance requirements, and installation techniques of FRP Hand Lay-up, SMC, and Pressed Steel Panel Tanks, you can make an informed choice that aligns with your specific needs and requirements.

Talk to us for your project today! WhatsApp or email – sales@muifatt.com.my . We guarantee our expertise to you.

Frequently Asked Questions

What is an FRP Hand Lay-up tank?

FRP Hand Lay-up tanks are constructed by hand-applying layers of fiberglass and resin, offering excellent corrosion resistance and versatility.

What is an SMC tank?

SMC tanks are made from a composite material consisting of fiberglass and resin, molded into smooth panels, providing high durability and resistance to corrosion.

What are Pressed Steel Tanks?

Pressed Steel Tanks utilize corrugated steel panels for robustness and strength, suitable for applications requiring mechanical impact resistance.

What are the key differences between FRP Hand Lay-up, SMC, and Pressed Steel Tanks?

FRP Hand Lay-up tanks are handcrafted, SMC tanks are molded, and Pressed Steel Tanks are hydraulically pressed.

Which tank material type is best for corrosive environments?

FRP Hand Lay-up and SMC tanks offer excellent corrosion resistance, making them suitable for corrosive environments.

Are Pressed Steel Panel Tanks suitable for outdoor applications?

Yes, Pressed Steel Panel Tanks are suitable for outdoor use due to their robust steel construction, which provides resistance to environmental elements and mechanical impacts.

What are the maintenance requirements for each tank type?

FRP Hand Lay-up and SMC tanks generally have low maintenance requirements, involving periodic inspections and cleaning. Pressed Steel Panel Tanks may require more maintenance, including repainting and inspecting seals.

How are sectional panel tanks installed?

Sectional panel tanks are installed by assembling prefabricated panels on site, using bolts, nuts, and sealant for secure connections.

What pressure test standards do these tanks follow?

FRP Hand Lay-up and SMC tanks typically adhere to industry standards such as ASTM. In the case of Mui Fatt FRP panel tanks, we comply with the standards outlined in BS EN 13280-2001. Pressed Steel Panel Tanks also adhere to standards like BS EN 13280.

How does the number of joints affect panel tank performance?

The number of joints in a panel tank can significantly influence its performance. More joints increase the risk of structural weaknesses, potential leaks, and maintenance requirements. Proper sealing and reinforcement of joints are essential to ensure the tank's integrity and longevity.

What is filler?

A filler is substance added to material, such as resin or polymer, to improve its properties or fill gaps. In composite materials like fiberglass or SMC (Sheet Molding Compound), fillers can enhance mechanical strength, control shrinkage, adjust density, or improve surface finish. Fillers are often used to tailor the characteristics of the material to suit specific applications.

Why is filler needed for SMC panels but not for hand lay-up panels?

Fillers are added to SMC (Sheet Molding Compound) panels to enhance their mechanical properties, density control, shrinkage control, and surface finish. In contrast, hand lay-up panels utilize pure resin and fiberglass without the need for additional fillers.

What is the advantage when we use pure resin and fiberglass in hand lay-up panels?

Using pure resin and fiberglass in hand lay-up panels offers precise customization to match application needs, leading to improved flexibility, customization, and potentially lower costs. This combination ensures excellent structural integrity and robustness. Fiberglass reinforces the resin matrix, making it strong and stiff, ideal for applications requiring durability. Tailoring the resin-to-fiberglass ratio further enhances structural properties to meet specific requirements.

Which tank material type is most cost-effective?

The cost-effectiveness depends on various factors such as installation complexity, maintenance requirements, and longevity.

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

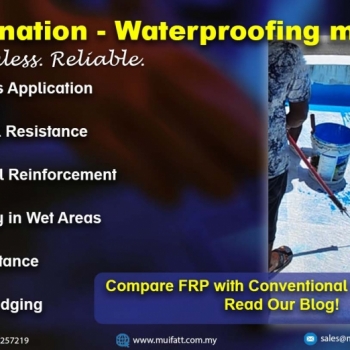

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

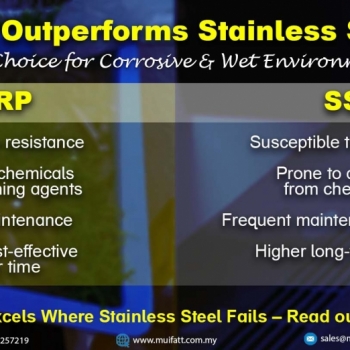

Mui Fatt Insights: Advanced Materials for Modern Needs

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

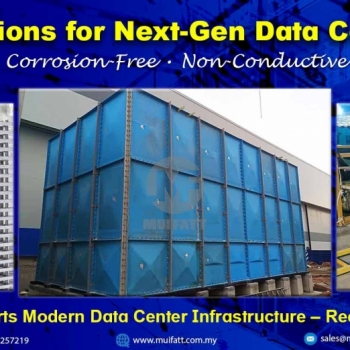

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.