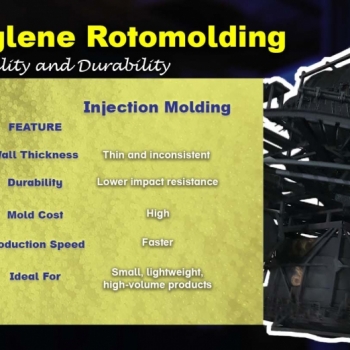

This article explains the polyethylene rotomolding process, compares it with other methods, and helps you decide the best manufacturing approach for your PE product needs.

Polyethylene: Recyclability and Sustainability

25 Nov 2024

Polyethylene Recyclability and Sustainable Solutions

- Key Takeaways

- Introduction: Why Polyethylene is the Future of Sustainability

- Understanding Polyethylene Recyclability

- Environmental Benefits of Polyethylene

- Our Polyethylene Product Range

- A Commitment to Sustainability

- Conclusion

- What makes polyethylene recyclable?

Key Takeaways

- Polyethylene is a Sustainable Material: Its recyclability and long lifespan make it a key contributor to reducing environmental impact and supporting a circular economy.

- Safe and Reliable Products: Mui Fatt ensures that all polyethylene products meet the highest safety and quality standards, especially for storing consumable water. This commitment to safety is crucial for maintaining public health and trust in our products.

- Environmentally Friendly Practices: Our manufacturing process focuses on durability, minimizing waste, and producing eco-friendly products using advanced rotomolding techniques. This innovative approach allows us to create high-quality items while mindful of our environmental footprint.

- Diverse Applications of Polyethylene: Our polyethylene products are designed for durability and efficiency across industries, from water tanks to playground equipment. This versatility demonstrates the material's adaptability and strength in various applications.

- Commitment to Quality Over Recycling: While polyethylene is recyclable, Mui Fatt prioritizes virgin materials for applications requiring maximum safety and compliance, such as water tanks. This decision underscores our dedication to quality and the well-being of our customers.

Introduction: Why Polyethylene is the Future of Sustainability

In today’s world, sustainability is more than just a trend—it’s a responsibility. Polyethylene (PE) has become an important part of the sustainability journey. PE is extremely durable and recyclable, making it a versatile and eco-friendly choice for manufacturers and consumers. Its minimal environmental impact further enhances its appeal in the quest for sustainable materials.

At Mui Fatt, a leading manufacturer of polyethylene products, we are committed to delivering quality and promoting environmental responsibility. In this article, we will explore whether polyethylene is recyclable and how it can benefit the environment.

We'll also highlight how our approach ensures safe, sustainable solutions customized to your needs.

Understanding Polyethylene Recyclability: What Makes It Sustainable?

Polyethylene is a thermoplastic material that can be reprocessed into new products without significant degradation. Its recyclability aids the global transition to a circular economy, where resources are reused rather than discarded.

Recyclable polyethylene uses less raw materials, saves energy, and reduces landfill waste. Industries and consumers can make a difference by switching to polyethylene. This choice decreases the overall effect on the environment; it's crucial in combating climate change.

How Does Polyethylene Recycling Work?

The process of recycling polyethylene involves several steps:

-

Collection: Polyethylene products, such as water tanks, rubbish bins, and packaging, are collected after their initial use.

-

Sorting: The collected materials are sorted based on their type and grade, ensuring efficient recycling.

-

Cleaning: To maintain the quality of recycled polyethylene, any contaminants like dirt, food residue, or adhesives are removed.

-

Shredding: The cleaned polyethylene is then shredded into smaller pieces or pellets, ready for reprocessing.

-

Reprocessing: The shredded materials are melted down and reformed into new products.

This closed-loop system helps reduce waste and ease the burden on landfills. It also preserves natural resources, reduces greenhouse gas emissions, and minimizes the environmental impact of polyethylene products.

Environmental Benefits of Polyethylene

Polyethylene offers significant environmental advantages compared to other materials, like metal or glass.

-

Energy Efficiency: Polyethylene production and recycling require less energy than metals or glass. That energy savings, in turn, means lower greenhouse gas emissions and a helping hand in fighting global warming.

-

Non-Toxic: Polyethylene is chemically stable, meaning it does not release harmful substances into the environment during use or recycling. This property ensures that polyethylene products are safe for everyday use and environmentally responsible disposal.

-

Long Lifespan: Polyethylene's exceptional durability gives its products long lifespans, minimizing the need for frequent replacements. This longevity significantly reduces overall resource consumption.

When you choose polyethylene products like water tanks and rubbish bins, you're helping create a greener, more sustainable future. We make products that last longer and can be recycled at the end of their lifespan, which helps reduce waste and preserve resources for future generations.

Assuring Safety: No Recycled Materials in Our Water Tanks

At Mui Fatt, we use premium-grade polyethylene for all our products. We demonstrate our commitment to the environment by creating safe, sturdy, long-lasting products. These efforts help keep waste down and our footprint small. Recycling is an important part of sustainability. However, we must be cautious and ensure our products are safe and high quality, particularly if they’re designed to hold consumables like water.

For this reason, we do not use recycled polyethylene materials in our water tanks. Water tanks are essential for storing water for homes and businesses, and keeping them safe is a priority for anyone who uses them. Recycled polyethylene is suitable for many applications but does not meet the strict safety standards necessary for products that store drinking water. At Mui Fatt, safety is our highest priority, which is why we exclusively use virgin polyethylene to manufacture our water tanks. This ensures the material is free from potential contaminants that could compromise water quality.

Why Virgin Polyethylene for Water Tanks?

-

Safety: Recycled polyethylene may contain impurities that compromise water quality.

-

Compliance: Virgin materials meet stringent safety standards for consumable water storage.

-

Durability: High-quality virgin polyethylene ensures long-lasting, reliable tanks.

Our septic tanks and playground equipment are crafted with high-quality polyethylene, ensuring superior performance and long-term reliability.

Our Polyethylene Product Range

We produce virtually every type of polyethylene product through the rotomolding process. This method ensures even wall thickness, strength, and excellent finishes.

Our product offerings include:

-

Water Tanks: Designed for safe water storage, using virgin polyethylene to meet the highest standards of quality and safety.

-

Septic Tanks: Durable, chemical-resistant solutions for wastewater management.

-

Planter Pots: Sustainable gardening solutions that are long-lasting and eco-friendly.

-

Bins: Weather-resistant and sturdy bins ideal for waste management in both residential and commercial settings.

-

Play Structures: Safe, durable, and customizable play structures designed for years of outdoor use.

-

Customizable Products: Tailored solutions for specific industrial and consumer needs.

A Commitment to Sustainability

As a company with more than 40 years of experience, we are committed to sustainability. We believe in investing in eco-friendly practices, from the materials we source to the way we make products.

Using the versatility and recyclability of polyethylene, we’re proud to help build a more sustainable tomorrow.

Conclusion

Polyethylene is a recyclable and sustainable material, offering energy efficiency and minimal waste generation to reduce environmental impact. Its recyclability aligns with our commitment to promoting eco-friendly practices.

For applications such as water storage, we prioritize safety by utilizing only the highest-quality virgin polyethylene. This ensures our water tanks meet the strictest safety standards while maintaining a balance between quality and sustainability.

Frequently Asked Questions (FAQs)

What makes polyethylene recyclable?

Polyethylene is a thermoplastic that can be melted and reformed multiple times without sacrificing structural integrity, which enhances its recycling potential and makes it a valuable material for plastic recycling initiatives.

Why don't we use recycled polyethylene in water tanks?

Safety is at the forefront of consumable water storage. Virgin polyethylene delivers the highest health and quality standards, ensuring the water remains safe for consumption.

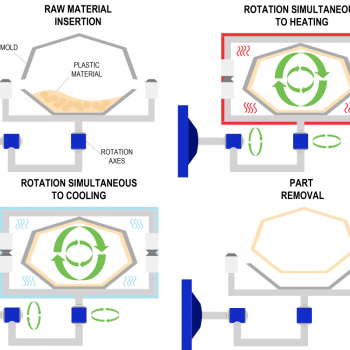

What is the rotomolding technique?

Rotomolding is a manufacturing process that enhances the potential of polyethylene, achieving even wall thickness and durability. Strong and consistent plastic products are produced by heating and shaping the plastic materials inside the mold while it’s rotated.

How does polyethylene contribute to sustainability?

Polyethylene contributes to sustainability in several ways. It is recyclable, durable, and efficient to produce. Additionally, it has little environmental toxicity, making it a more eco-friendly option compared to other materials.

Disclaimer:-

The content on this site is for general information and entertainment purposes and does not constitute legal counsel. We strive to keep our information as accurate as possible. However, we make no warranties about the completeness, accuracy, reliability, suitability, or availability with respect to the information contained on this page. You should rely on this information at your own risk. This website may include links to other third-party sites. These links are provided as a convenience to you as a reader, user, or browser only. We make no representation, warranty, or guarantee, nor do we endorse or take responsibility for any of the content of such sites.

Stay in touch with us if you’re interested in hearing from us promptly.

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

The Art of Rotomolding: Durable Polyethylene Planter Pots

Discover the manufacturing marvel of rotomolding! Learn why this process ensures durable planter pots and other polyethylene products with exceptional quality.

Are Plastic Flood Barriers the Solution to Malaysia's Flood Crisis?

Flooding in Malaysia is increasingly common. Explore how plastic flood barriers could be a game-changer.

Scheduled Water Disruption Penang: Essential Tips for Preparation and Resilience

Get essential tips for preparing and staying resilient during scheduled water disruption in Penang. Don't miss out, read more now! #waterdisruptionpenang

A Complete Guide to Brass Float Valves with Copper Balls

Learn how the robust construction of brass and corrosion-resistant properties of copper make these valves ideal for PE water tanks. Discover the benefits, applications, and maintenance tips for ensuring optimal performance in industrial, agricultural, and other settings.

Rotomolding vs. Injection Molding for Plastic Dustbins: Pros and Cons

Rotomolding and injection molding are two common methods used for manufacturing plastic dustbins. This article compares the pros and cons of each method to help you decide which is right for your needs

Is Plastic Water Tank Safe?

Is potable water stored in a PE water tank safe to be consumed?