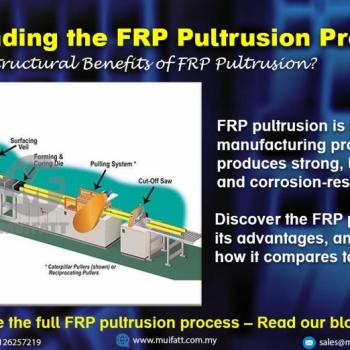

FRP pultrusion is a continuous manufacturing process that produces strong, lightweight, and corrosion-resistant profiles. This article explains how the process works, its advantages, and how it compares to other FRP fabrication techniques, helping you choose the right material for your project.

Relationship between Polymer Science and Mechanical (Composite Materials)

24 Feb 2023

Fiberglass (or glass-reinforced plastic) is a type of thermoset polymer. It is Epoxy, Resin, or Vinlyester, or a Thermoplastic Polymer that has been reinforced with Glass Fibers.

Polymer composites are a combination of polymers (eg. Thermosets or Thermoplastics) with various continuous and non-continuous reinforcements/fillers (In Mui Fatt’s business – Glass Fibers), principally added to polymers to improve the material performance. Polymer composites are increasingly being used in various engineering fields. For instance, chemical/petrochemical, power, water/wastewater, microelectronic, pharmaceutical, residential and municipal councils.

Polymer composites are a combination of polymers (eg. Thermosets or Thermoplastics) with various continuous and non-continuous reinforcements/fillers (In Mui Fatt’s business – Glass Fibers), principally added to polymers to improve the material performance. Polymer composites are increasingly being used in various engineering fields. For instance, chemical/petrochemical, power, water/wastewater, microelectronic, pharmaceutical, residential and municipal councils.

Who is required in this area?

Experts needed for fiberglass manufacturing includes Polymer Science Engineer and Mechanical Engineer (specifically in Composite Materials). Let’s differentiate the responsibilities for both.

Routine for Polymer Science Engineer covers but not limited to material selection (matching material to application requirements especially), formulation and processing, quality control and testing, research and development (ideally in developing new materials and tools for use in fiberglass composites), and troubleshooting.

Routine for Polymer Science Engineer covers but not limited to material selection (matching material to application requirements especially), formulation and processing, quality control and testing, research and development (ideally in developing new materials and tools for use in fiberglass composites), and troubleshooting.

Where Mechanical Engineer play an important role in the development, design, and analysis of fiberglass composite. This includes determining the appropriate material and thickness for the components, develop and implement testing and validation procedures to ensure the fiberglass composite meets the desired specifications and is free of defects. In case there is a failure or defect, mechanical engineer will conduct a failure analysis to determine the root cause and develop corrective actions to prevent future occurrences.

Where Mechanical Engineer play an important role in the development, design, and analysis of fiberglass composite. This includes determining the appropriate material and thickness for the components, develop and implement testing and validation procedures to ensure the fiberglass composite meets the desired specifications and is free of defects. In case there is a failure or defect, mechanical engineer will conduct a failure analysis to determine the root cause and develop corrective actions to prevent future occurrences.

In general, while Polymer Science Engineer and Mechanical Engineer (Composite Material) have different areas of expertise, their skills and knowledge can certainly complement each other in the context of fiberglass manufacturing. One helping to select the appropriate materials, optimizing the processing parameters, ensuring quality control, conducting research and development, and troubleshooting any issues that may arise. Another, ensuring that the components and structures are designed and manufactured to meet the required specifications and perform to the intended standards. Their expertise in design, analysis, and testing can help to optimize the manufacturing process, improve the product quality, and enhance the overall performance of fiberglass composites.

We are having open recruitment for both Polymer Science Engineer and Mechanical Engineer (Composite Materials) currently. Fresh Graduates from Diploma or Degree are encouraged to apply. Understand more from Mui Fatt Open Recruitment

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

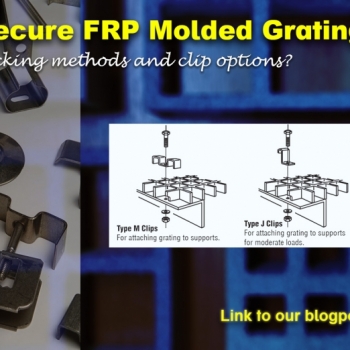

The Ultimate Guide to Locking Mechanisms for FRP Molded Grating

Understanding the right locking method for FRP molded grating is crucial for safety and durability. Learn about M clips, J clips, C clips, and disk plates, along with installation recommendations to ensure a secure and stable grating system.

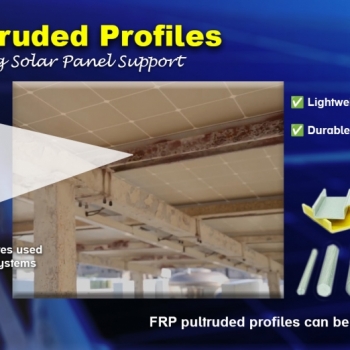

Enhancing Solar Panel Fixing Structures with FRP Lamination: A Corrosion Barrier Solution

An expert look at how FRP lamination acts as a corrosion barrier for solar panel fixing structures, offering advanced protection and sustainability benefits.

Steel Fixing Structures in Solar Panel Installations: Corrosion Challenges and Alternative Materials

An in-depth look at the corrosion challenges faced by steel solar panel fixing structures and alternative materials that offer enhanced durability and sustainability.

The Essential Guide to Kickplates: Safety, Style & Compliance

Learn why kickplates matter for safety, style, and compliance. Discover how they improve accessibility and meet building code requirements.

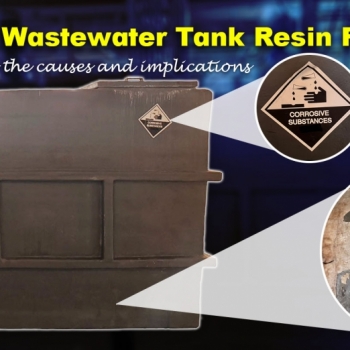

The Costly Mistake of Using Unsuitable Resin for FRP Tanks

Explore the risks of unsuitable resins for FRP wastewater tanks, including a real-life example of NaOH corrosion. Learn how to avoid costly failures.

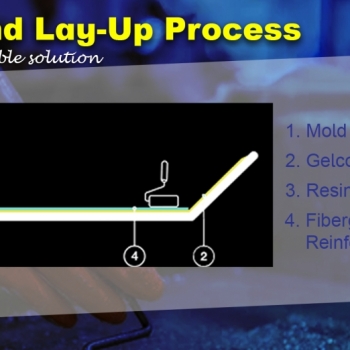

Mastering the FRP Hand Lay-Up Process: Methods, Benefits, Sustainability

Discover the FRP hand lay-up manufacturing process, its importance, differences from other methods, and how it aligns with your custom project needs.

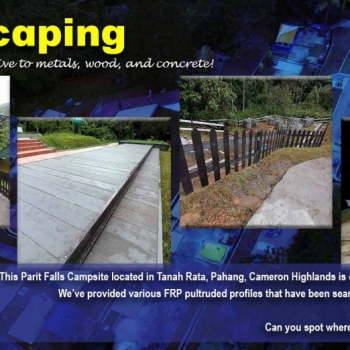

Transform DIY Projects with FRP Pultruded Profiles

Explore the versatility of FRP pultruded profiles and how they can elevate your DIY landscaping projects. Get inspired by Mui Fatt's successful applications and learn how to create custom solutions for small- to larger-scale projects.