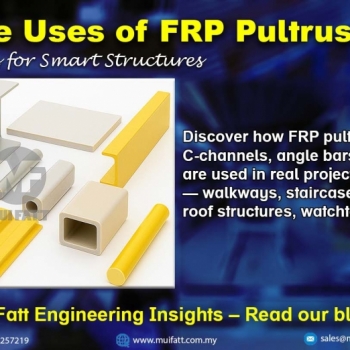

FRP pultruded profiles are reshaping structural possibilities across Malaysia. From STP staircases to public park shelters, explore how these modular components enable custom FRP solutions—only from Mui Fatt.

Site Hoarding and FRP Roofing Sheet

18 Apr 2023

In Malaysia’s construction industry, site hoarding materials play a vital role in providing security and privacy to ongoing projects. However, a common issue arises when these traditional materials such as metal fences quickly become rusted, despite appearing well-maintained from the outside, leading to increased costs and potential safety hazards.

Why Site Hoarding Materials Rust Easily?

Site hoarding materials in Malaysia are prone to rusting for several reasons. Firstly, the tropical climate, characterized by high humidity and frequent rainfall, accelerates the corrosion process. Moreover, some developers who prioritize cost reduction may opt for cheaper materials that are more susceptible to rust. By implementing a “buy cheap, buy new” strategy, they invest less initially. While this cost-saving measures may seem practical at first, they often result in increased maintenance and replacement costs in the long run. Furthermore, the use of inferior materials can compromise the safety and structural integrity of the fences, posing potential hazards to both construction workers and the general public.

Site hoarding materials in Malaysia are prone to rusting for several reasons. Firstly, the tropical climate, characterized by high humidity and frequent rainfall, accelerates the corrosion process. Moreover, some developers who prioritize cost reduction may opt for cheaper materials that are more susceptible to rust. By implementing a “buy cheap, buy new” strategy, they invest less initially. While this cost-saving measures may seem practical at first, they often result in increased maintenance and replacement costs in the long run. Furthermore, the use of inferior materials can compromise the safety and structural integrity of the fences, posing potential hazards to both construction workers and the general public.

The importance of Proper Site Hoarding Maintenance

Proper maintenance is essential for preventing rust and ensuring the longevity of site hoarding materials. Developers should prioritize regular inspections and timely repairs to avoid costly replacements and safety risks. Additionally, applying anti-rust coatings can significantly reduce the likelihood of rust formation. However, it's important to note that these measures may incur additional costs.

If you're looking for an innovative alternative to traditional site hoarding materials, consider fiberglass roofing. Not only does it offer numerous benefits, such as reducing long-term costs and ensuring the safety of construction sites, but it also contributes to a more sustainable construction industry. In this article, we'll explore the advantages of fiberglass roofing and its potential to revolutionize the construction sector in Malaysia.

Advantages of Fiberglass-Reinforced Plastic (FRP) Roofing as Site Hoarding Material

Corrosion Resistance

Unlike metal fences, FRP roofing is resistant to rust and corrosion, making it ideal for Malaysia’s tropical climate. This durability ensures that site hoarding remains secure and aesthetically pleasing throughout the construction process.

Lightweight and Easy to Install

FRP roofing is significantly lighter than metal fences, making it easier to transport and install. This lightweight characteristic reduces labour costs and accelerates the site hoarding installation process, ultimately saving both time and money.

Low Maintenance

FRP roofing requires minimal maintenance, as it does not corrode or rust like metal. This low maintenance requirement translates to decreased long-term expenses and increased cost-effectiveness for developers.

Customizable and Aesthetically Pleasing

FRP roofing can be customized to suit various design preferences, allowing developers to create visually appealing site hoarding that blends seamlessly with the surrounding environment. This customization also provides opportunities for branding and promotional activities during construction.

Environmentally Friendly

FRP roofing is a more sustainable option compared to metal fences, as it requires fewer resources to manufacture and has a longer lifespan. By choosing FRP roofing as a site hoarding material, developers contribute to a greener construction industry.

Ultimately, Fiberglass-Reinforced Plastic (FRP) Roofing presents a promising alternative to traditional site hoarding materials in Malaysia’s construction industry. Its corrosion resistance, lightweight nature, low maintenance requirements, customizable design, and environmentally friendly properties make it an ideal choice for developers seeking cost-effective and sustainable solutions. By embracing innovative materials like fiberglass roofing, Malaysia’s construction sector can enhance efficiency, reduce long-term costs, and promote environmental sustainability.

Ultimately, Fiberglass-Reinforced Plastic (FRP) Roofing presents a promising alternative to traditional site hoarding materials in Malaysia’s construction industry. Its corrosion resistance, lightweight nature, low maintenance requirements, customizable design, and environmentally friendly properties make it an ideal choice for developers seeking cost-effective and sustainable solutions. By embracing innovative materials like fiberglass roofing, Malaysia’s construction sector can enhance efficiency, reduce long-term costs, and promote environmental sustainability.

Allowed us to eliminate the source of frustration for you, talk to us for your project today! WhatsApp or email – sales@muifatt.com.my

We guarantee our expertise to you.

Visit our product page for more product details – Fiberglass Site Hoarding Sheet

Disclaimer:-

The information provided on this website is for general informational purposes only and does not constitute legal advice. While we strive to ensure the accuracy and reliability of the information provided, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability concerning the information contained herein. Any reliance you place on such information is therefore strictly at your own risk. This website may contain links to other third-party websites. Such links are only for the convenience of the reader, user, or browser; which we do not warrant, recommend, endorse, or assume liability for the contents of the third-party sites.

Keep in touch with us should you be keen on receiving timely updates from us

- Website - https://www.muifatt.com.my/home/

- Facebook - https://www.facebook.com/muifattmarketing

- Instagram - https://www.instagram.com/muifattmarketing/

- Google - https://goo.gl/maps/WxVY13gNcaRTS7Jp6

- Youtube - http://www.youtube.com/@MuiFattMarketing

- TikTok - https://www.tiktok.com/@muifattmarketing

- LinkedIn - https://www.linkedin.com/company/mui-fatt-marketing-sdn-bhd-

- Linktree - https://linktr.ee/muifattmarketing

- Shopee - https://www.shopee.com.my/muifattmarketing

- Lazada - https://www.lazada.com.my/shop/mui-fatt-marketing

Recent Blog

Mui Fatt Engineering Insights - FRP Panel Tank Installation

Get to know the step-by-step assembly process of FRP sectional panel tanks, based on Mui Fatt’s industry-proven practices. This easy-to-digest guide is ideal for project managers, contractors, and technical personnel involved in water storage tank installation across Malaysia.

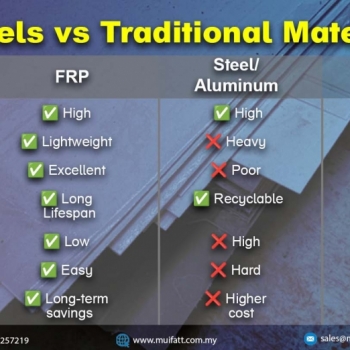

FRP Panels vs Traditional Alternatives: The Ultimate Guide to Durability and Sustainability

Explore why FRP (Fiberglass-Reinforced Plastic) panels outperform traditional materials like steel, plywood, and PVC in durability, sustainability, and cost-effectiveness. Discover real-world applications in MyKiosk projects and cold truck panel assembly, where FRP’s superior insulation, corrosion resistance, and lightweight properties deliver long-term benefits.

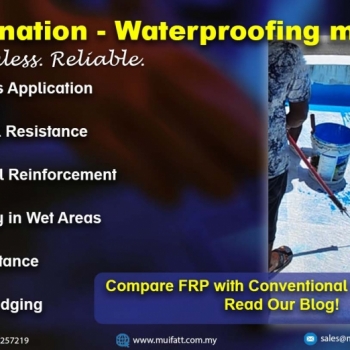

Comparing FRP Waterproofing with Traditional Systems

Is FRP lamination a better waterproofing method than traditional systems? Explore this complete guide with real project examples and see why FRP is gaining traction across Malaysia.

Benefits of FRP in Food Handling & Processing

With hygiene, durability, and corrosion resistance at its core, FRP (Fibreglass Reinforced Plastic) is becoming a preferred material in the food industry. This article explores why FRP is ideal for food handling equipment such as supermarket fish trays, water tanks, and food factory platforms, plus how Mui Fatt is delivering proven solutions through its successful FRP applications.

Mui Fatt Insights: Advanced Materials for Modern Needs

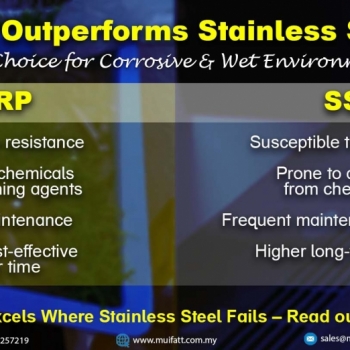

Is stainless steel the best for wet areas? This article explains why more industries are switching to FRP for its corrosion resistance, hygiene benefits, and longevity, especially in food displays and chemical exposure zones.

How FRP Supports Modern Data Center Infrastructure

Discover how fiberglass-reinforced plastic (FRP) is reshaping data center construction. Learn its key advantages, comparisons with other materials, and where to apply FRP—from rooftop chillers to cooling tanks.

Understanding FRP Filament Winding: Process, Benefits & Comparison

This article explores the FRP filament winding manufacturing method, how it differs from other FRP techniques, why it’s still widely used, and its long-term value for projects like high-strength tanks and cylinders.